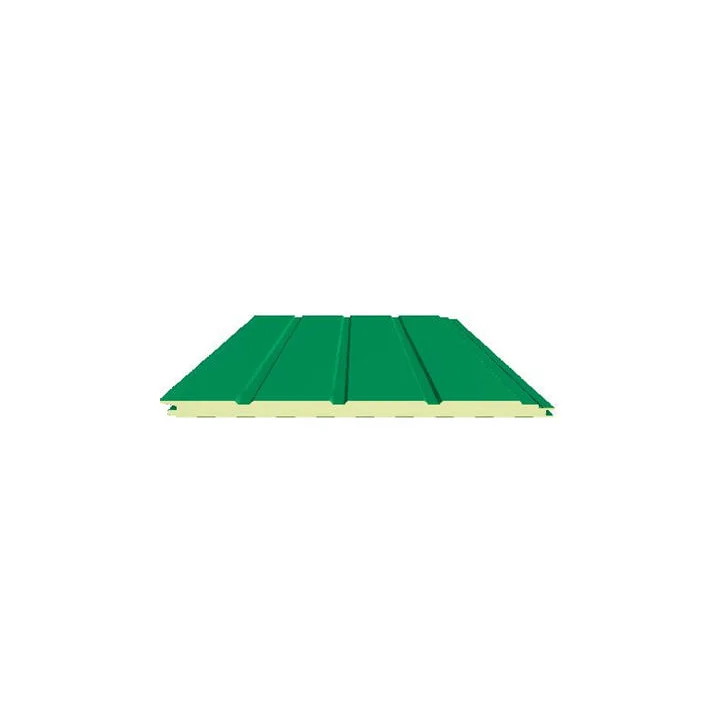

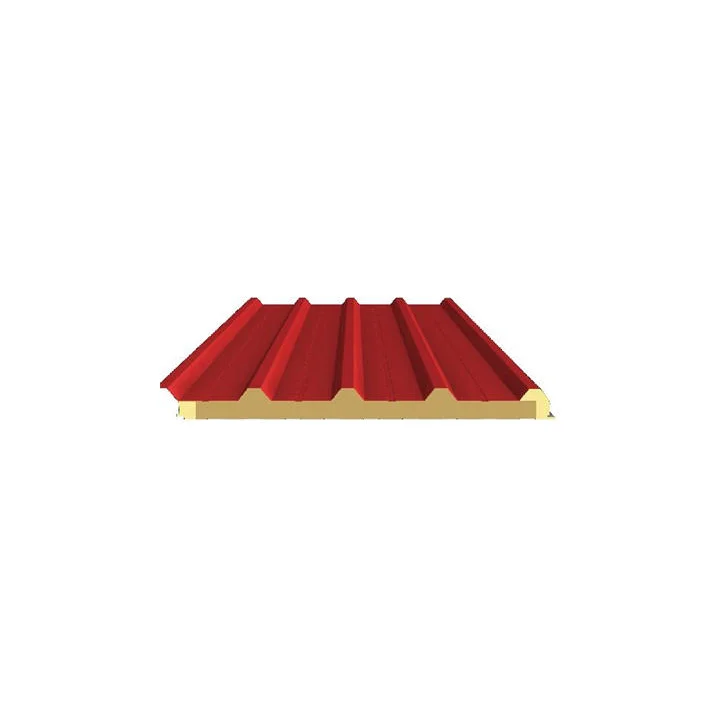

PU sandwich panel machine from china are getting popular in Chile. These are the machines that produce special wall and roof panels that insulate buildings to keep them warm and strong. These machines are made by zhongji company with much care and precision. A lot of Chilean factories would like to buy machines like these, because they save time and make for better products. The way the machines do their work is fascinating; they combine materials and force them into solid layers fast. This is valuable for areas that are constructing new homes, offices or even big warehouses. With zhongji PU sandwich panel machine, Chilean factories can work faster and effectively in all their daily output of lots of panels every day. For more information on the production process, you can check out Assembling 3D Panel Machines.

Chile’s factories have to work fast and make perfect panels every time. Zhongji PU sandwich panel machines can facilitate this. For one, these machines perfectly mix polyurethane foam with metal sheets. That creates panels that are less likely to crack and better at holding in heat. The machine carefully regulates its temperature and pressure, so that every panel is formed in the exact same way. Think about making hundreds of panels by hand — that would be time consuming and quality can vary. But with zhongji machines, everything is easy and fast. Once the machine is set up, it runs on its own, so employees do not get tired and make mistakes. And that’s less waste, which costs money.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ