What is a PU Sandwich Panel Machine Production Line and Its Benefits in Chile

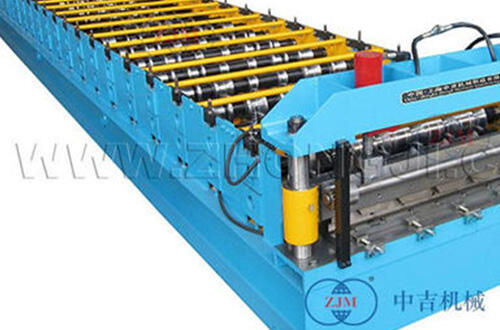

Choosing the best PU sandwich panel machine production line wholesale in Chile is not an easy task. There’s a lot to consider when buying, and you want the best machine for your needs and budget. First, consider how many panels you would like to make each day. A few machines can make relatively small quantities, which might be suitable for novices or small businesses. Neither can make hundreds or thousands of panels, ideal for big factories. Production line sizes Zhongji offers a variety of production line sizes, so you can find one that suits your company whether you’re starting out or already big. Then consider the quality of the machine and how easy it is to use. A machine that needs frequent repairs or cannot be repaired at all is going to end up costing you more money in the long run. Zhongji’s machines have easy controls and are fabricated with durable parts, meaning you’ll spend less time in need of repair. This helps keep the factory humming and the downtime at a minimum. Another key thing is how much space you have in your factory. Some assembly lines are large and require a lot of space, others small enough to fit into more confined quarters. Consider Your Factory Layout Before You Decide. Also worth verifying: Can the machine create panels in a variety of sizes or thicknesses, which will allow you to generate options that appeal to as many of your customers — with their myriad needs and quirks! — as possible? Last, inquire about support and service from the business. Effective after-sales support is getting help quickly if something goes wrong. And Zhongji provides sound after-sale service to all the buyers in Chile, you won't feel alone though you are using our machine. They also provide training so your employees can be trained to operate the machines safely and effectively. Selecting your PU sandwich panel machine production line is a big step, but if you consider the speed, quality and size you need along with flexibility and support that can help you constantly scale, then you will find what fits best for your business in Chile.

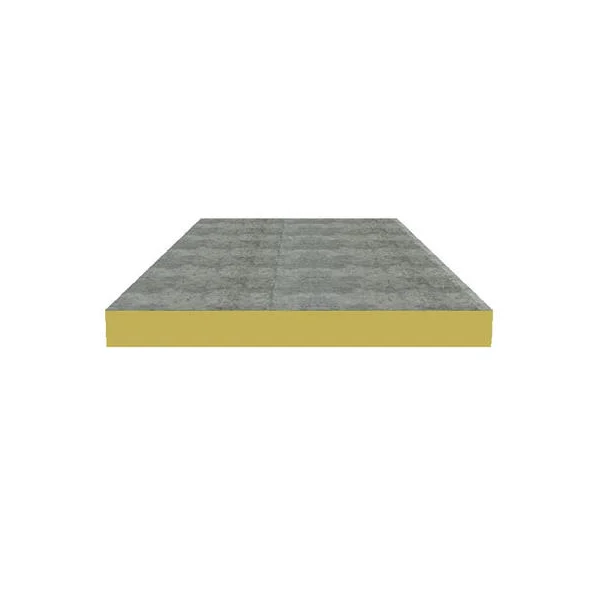

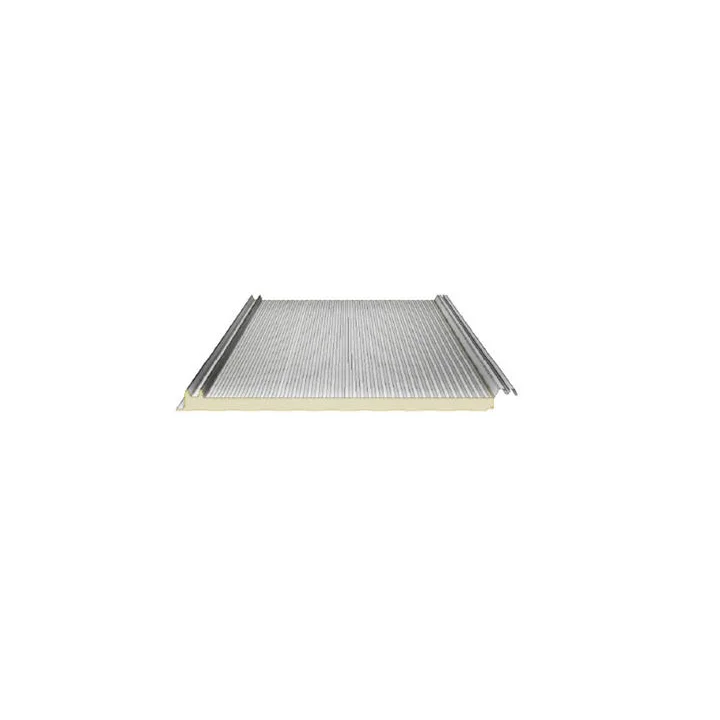

If you are searching for a high quality place to purchase a PU sandwich panel machine production line in Chile, then it is crucial that you find reputable suppliers which can provide the machinery you need. The PU sandwich panels is a kind of special building materials, with two metal plates for the external layer as well as polyurethane foam in the middle. Such panels are strong, lightweight and effective at insulating buildings from heat or cold. In order to create these panels, you must use a PU sandwich panel machine production line which consists of a few machines that can work together to make the panels fast and accurately. For example, machines like the low pressure foaming machine and Packing Machine are essential in this process.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ