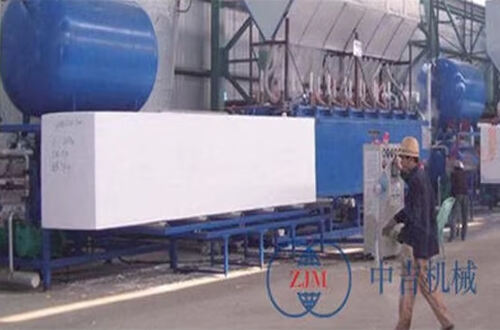

Mineral wool sandwich panels are a kind of special architecture products which play an important role in maintaining warm and safety. Those panels are created by sandwiching a layer of mineral wool, which is both strong and fire-resistant, between two sheets of metal. These panels are made with a special machine. In Chile, Mineral Wool Sandwich Panel Production Line When a lot of factories want to buy good machines for producing mineral wool sandwich panel in Chile which have construction areas get bigger and bigger. Zhongji builds those machines, which are valuable to companies looking to produce these panels quickly and well. These machines can save times and money, and make strong panels that are durable.

If you need to purchase a mineral wool sandwich panel machine wholesale in Chile, it can be difficult to choose the best one. A lot of things have to be re-evaluated. First consider how much the machine can produce per hour. If you are a business and want to sell lots of panels, you need a machine that goes fast. But if you are purchasing the machine specifically for small tasks, a slower one may be sufficient. Also, consider how easy it is to use the machine. Some machines are difficult to operate and such engines require special training. (A few are easier, so workers can pick up the tasks relatively quickly. Another consideration is how big you want the panels to be. Your machine needs to be able to produce the size that’s right for your customers. For instance, if customers want large panels for walls, the machine should be able to accommodate that size without issue. Zhongji’s machines come in different sizes and speeds, which would make them suitable for many businesses. Also, ensure the machine is sturdy and durable. If the machine breaks frequently, money will be wasted in repairs and work will drag. Seek out machines built with sturdy and tested materials to last a long time. Some models will have extra parts that simply make good sense, and will be easier to fix when the time comes. Don’t ignore how much power the machine is using. Machines that use less electricity can save money. Also consider where you will house the machine in your factory. Big, small — machines come in a range of sizes. Zhongji creates machines suited to smaller spaces so you can run them in tiny and larger factories. Last but not least, consider the company that sells the machine. You also want to buy from a seller who assists with installation and repair. Zhongji has a reputation of guiding customerservice after the sale of machine. This help is critical, as machines sometimes need tweaking and parts replaced. It’s going to take a little bit of time for you to do it but, if you pay attention to these a few things, you will get one that can help you grow your company and make good machine in Chile.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ