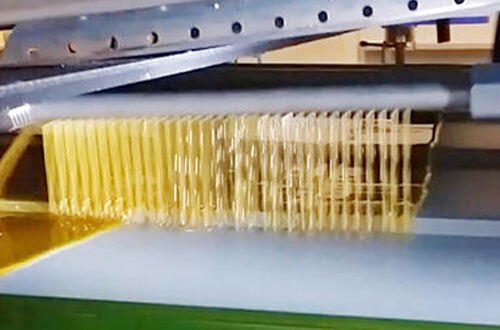

EPS batch pre expander is an extremely efficient piece of equipment that can significantly reduce cost and production time, making it one of the most important machines when working with expanded polystyrene. It’s this process that makes things such as packaging, insulation and thousands of other products. American made machines such as zhongji are known for their quality and intelligent design. These machines enable factories to produce a good foam product by quickly and evenly expanding beads. In the batch process, the machine receives a certain quantity of beads at one time and is able to control where they expand. An eps batch pre expander machine from zhongji will make your job easy, fast and energy efficient. Because this type of machine allows various amounts of beads it can process, it is suitable for both small companies and large factories. There needs to be some sort of standardization. These machines are just built to last forever, and easy to repair as well – we can’t have downtime on a busy line. Zhongji also provides user support and clear instructions even for those who aren’t experts when it comes to machines, making sure that you can start using the pre expander without issues.

Wholesale buyers of EPS batch pre expander machines are looking for something that won’t let them down can be extremely efficient as well good value for money. Machines made in the USA, such as zhongji’s, excel by covering four band and using intelligent technology. Most machines also are better insulated, keeping more of that heat inside, so less energy is wasted in the expansion process. This is money-saving in the long run – especially if you’re running many runs each day. Wholesale clients are similarly looking for machines that can manage large quantities of beads all at once, and zhongji’s models come in multiple sizes, with which manufacturers, including many of these smaller players, can scale production. Also worth noting is the ease with which it can be cleaned and maintained. If a machine is down or needs repairing frequently, production can slow and extra money can be spent. That’s why zhongji builds their machines using simple parts that can be changed out fast with no special tools. Other machines may be faster, but use too much energy, or have to be repaired frequently. The USA-factory machines strike a happy medium, delivering good speed while also saving power. And zhongji offers wholesale buyers training and support, so they don’t have to stress about the learning curve or troubleshooting on their own. The reputation of USA-made equipment also helps buyers who wish to sell these machines to other businesses win the trust of their customers. With trust comes the potential for more sales as well as an improved business growth. Wholesale buyers value machines that do not age and will not let them down, so they can produce more products without loss of time. The machine is only as good as one’s experience with the quality and service behind it.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ