How EPS Sandwich Panel Making Machines Improve Product Quality and Efficiency

Good machines that aren’t too expensive can also be hard to find. In Palestine, many shoppers seek reliable sources that can offer them wholesale prices. Zhongji can provide these machines at reasonable prices, which make them affordable for small and medium businesses to purchase without investing a lot money. Purchasing in wholesale means buying more than one macine or placing a bulk order and the cost for each machine will generally be lower. That is useful for companies that hope to begin or expand production of panels. "Moreover, in addition to the price offers, zhongji also fully supports all buyers from Palestine. That includes installation assistance, training for workers and fast repairs if something breaks. Some sellers simply ship the machine and leave buyers to their own devices, but with zhongji, customers are supported through every phase. As the company is aware of what can be challenging in Palestine, like shipping delays or customs rules, they plan ahead and take measures to prevent issues. Plus, zhongji machines have solid warranties so buyers can feel good about their purchase. Several factories that purchased these machines say they were able to do more work faster and better, which in turn helped them win new customers. if you seek to know the best offer, welcome contact zhongji directly for more details and then get your favorite product. There are also instances where ordering in larger groups with other factories can drive costs down even further. And zhongji machines are durable, so it seems a good use of money in the long run. no experience? no problem!zhongji team may help you for type selection of reliable good quality machines which suit to your market in Palestine.

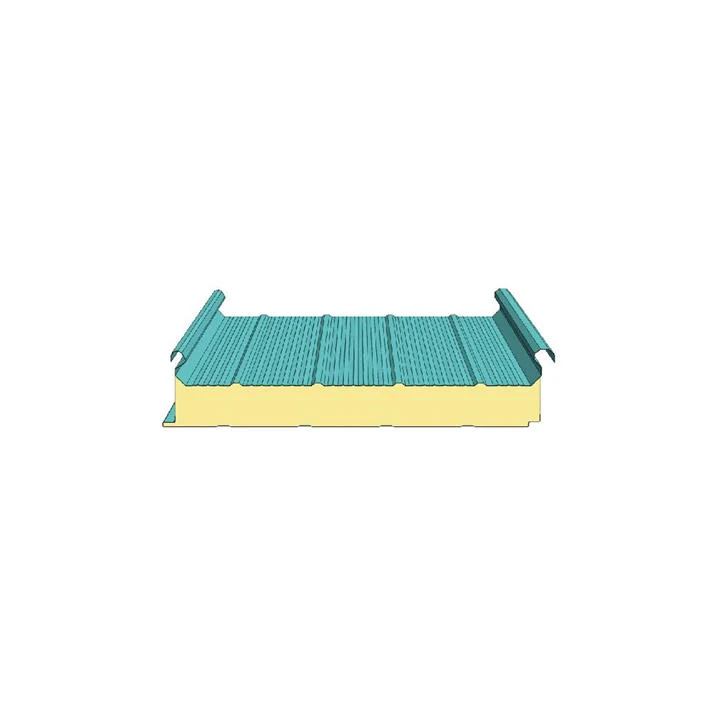

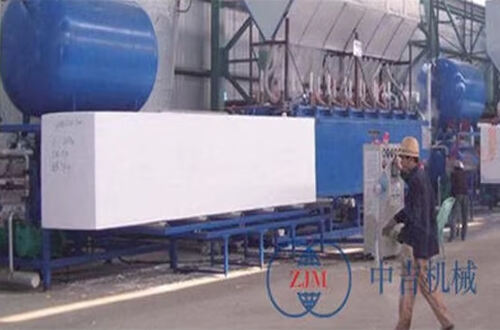

In order to maximize the potential of an EPS sandwich panel making machine such as those from Zhongji, workers need to have a good understanding on how it functions. First off, make sure you have everything ready. The size of the EPS foam needs to be cut and the metal sheets need to be clean, as well. Zhongji machines often come with automatic feeders that get the metal sheets and foam where they need to be, saving time and cutting down on mistakes. And these machines don’t have to take a break, so factories can produce many panels in a single day.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ