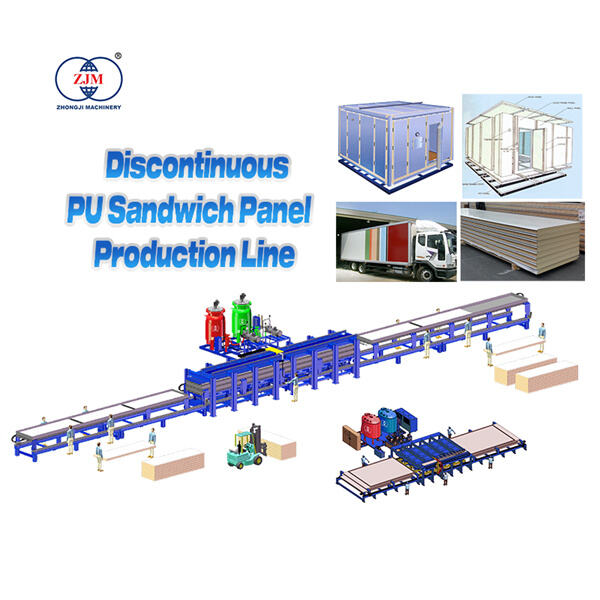

Zhongji is glad to post our manual to operate sandwich panel making machine. This guide should teach you the exact method to produce high quality sandwich panels with your machine. We have made this user-friendly guide because we want you to do a good job and earn money when you are making sandwich panels. Under our guidance, we believe that you will be an expert hands on in any time. So, without further ado, let us embark on this thrilling journey!

If you are just getting started with your sandwich panel producing equipment, it can be a bit intimidating or a little confusing. But don’t worry! Just follow our simple step-by-step instructions and you’ll become an expert in no time. The first step is to prepare all the materials. You also need foam, metal sheets, and glue. Ensure that you have everything at arm’s reach to allow you to work effectively.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ