Enhanced Insulation and Structural Benefits with Polyurethane Sandwich Panel Lines

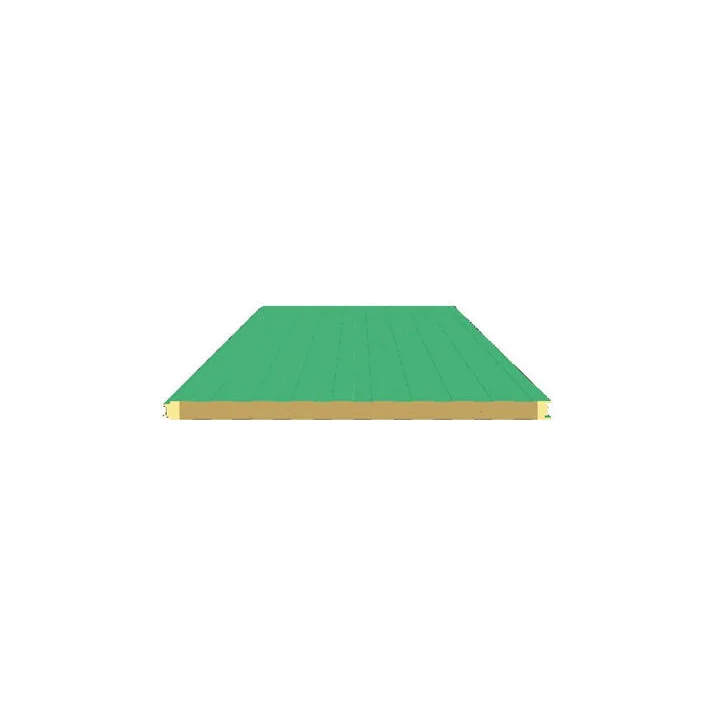

These panels are so effective because they use a polyurethane material to create them. This thing is a beast at insulation and will hold whatever tempurature temperature it feels onbtge outside inside. Since insulation helps in insulating the walls of building it results in energy saving. Polyurethane is also known to be extremely durable and it does not crack or create bearings on its outer surface that could cushions the load of say a roofing structure been placed upon this material.

Of course, one of the main benefits of these machines is that they can produce panels in a variety of shapes and sizes. This type of machine is used, for instance, when you need super-thin panels — say slivers a fraction as thick as a regular board — in some specific area on the building. Conversely, if you need the machine to make thicker and stronger panels for higher use areas it can do this as well. This flexibility puts the materials directly into builders' hands in a way that matches exactly what they need to build.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ