What Are the Key Features of PU Sandwich Panel Machine Line in Chile?

What Chile’s construction projects do need are materials that are strong and light and good at conserving energy. The PU sandwich panel machine line of zhongji make has these specifications fitting well. The machine line is good partly because the panels it creates keep buildings warm in winter and cool in summer. This is significant in Chile, for instance, where the weather can change substantially from north to south. The need for additional heating or cooling is minimized by the panels, saving money and benefiting the environment. Chilean builders also appreciate that the panel produced by zhongji’s machine line is easy to carry and install. This speeds up the construction process, especially in remote areas or on hills. The panels are also strong yet lightweight, so workers do not have to use big machines to shift them. Another good point is quality. The machine line creates panels without the cavities or voids in the foam layer that can spring up over time, causing the panel to lose heat. This is why buildings remain safe and comfortable for so long. The line also allows factories to produce panels fast, a good fit for Chile’s expanding building market. Whether you are erecting new homes or big warehouses, the panels go up quickly. Because the machine can be configured in different ways, factories are able to make panels with colors or special metal sheets, which allows builders to achieve varied looks for buildings. This is a major plus for architects and builders who desire something unique. The machine line’s simplicity of operation allows workers to learn quickly, have the load off their minds during high-volume orders and retain more mental energy. This keeps the job smooth, in case a lot of panels are required at the same time. On these considerations, zhongji’s pu sandwich panel machine line is a good fit with Chilean construction contracts, will save their space – it does not require much room to operate – money and effort while delivering hardy, energy smart buildings. For instance, the integration of the low pressure foaming machine enhances efficiency in producing these panels.

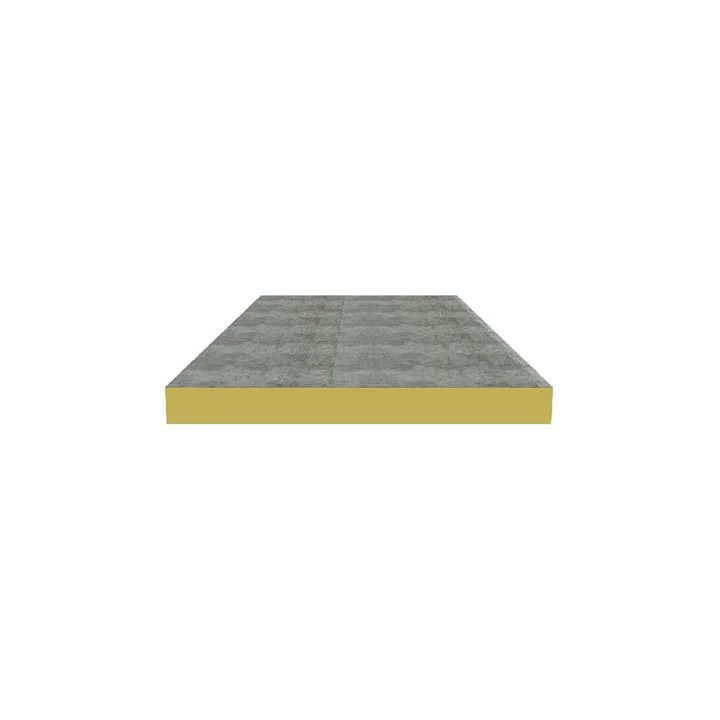

The PU sandwich panel machine is a special machinery suitable for manufacture of the construction material such as the polystyrene PU foam colorful steel sandwich type panel used for the external and internal wall, roof and wall panel of cold storage, and more. In Chile, this zhongji machine line has shown that changes in product quality and production speed. First, the machine line mixes and squirts out polyurethane foam very evenly between two metal sheets. That — along with a light, rigid panel that keeps heat out or in (depending on where the building is located) — is critical for buildings across different climates. “The machine does all the heavy lifting,” he said, in terms of controlling how much and temperature of materials come together, meaning each panel comes out solid and without weak spots. Which means the panels last longer and buildings stay safer and more comfortable. The cut-off (shearing) device is another essential component that ensures precision in panel production.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ