How Sandwich Panel Machine Polyurethane Enhances Energy Efficiency in Chilean Buildings

Sandwich panel machines with polyurethane is not easy all the time. Occasionally things go wrong that slow down work or make panels less good. Foamy bubbles or cavities in the panel are one frequently reported problem. This weakens the insulation when air can flow through such bubbles with ease. Typically, bubbles result when the machine’s temperature or pressure is not adjusted correctly. Zhongji noticed that tightly inspecting machine settings before beginning prevents bubbles. And cleaning the machine’s molds and pumps regularly will prevent dirt or old foam from entering. Other issues include the foam not adhering properly to metal sheets. When the surfaces are wet, or dusty, the foam flakes off later. To prevent that, workers have to clean and dry sheets before running them through the machine. Zhongji machines come equipped with sensors that alert when sheets are not properly installed or possessed for good bonding. Occasionally the machine’s foam mix is off. Polyurethane is made by combining two parts, and if the proportions are not correct, the resulting foam may be mushy or crumbly. Operators calibrate the chemical mix by hand and tailor them to the weather and panel size. Zhongji trains its operators to observe the foam closely during the production process in order to spot changes early. Another challenge is the breakdown, or slowdown, of machines due to old parts and lack of maintenance. Pumps, heaters and cutters in regular service keep them operational and doing a good job. Zhongji also provides service consultation and helps customers plan maintenance schedules based on production demands. Last, panels can warp if cooled improperly or stacked improperly after forming. This can destroy the panels, or make them difficult to install. To address that, workers allow the panels to cool on their own, and stack them flat, with space between layers. Training is crucial; Zhongji ensures that its users understand these steps to achieve the best panels possible each time. Things can go wrong, but with good care, correct settings and expert assistance from Zhongji, sandwich panel machines are churning out first-rate polyurethane panels that keep Chile’s construction sites safe and energy-smart.

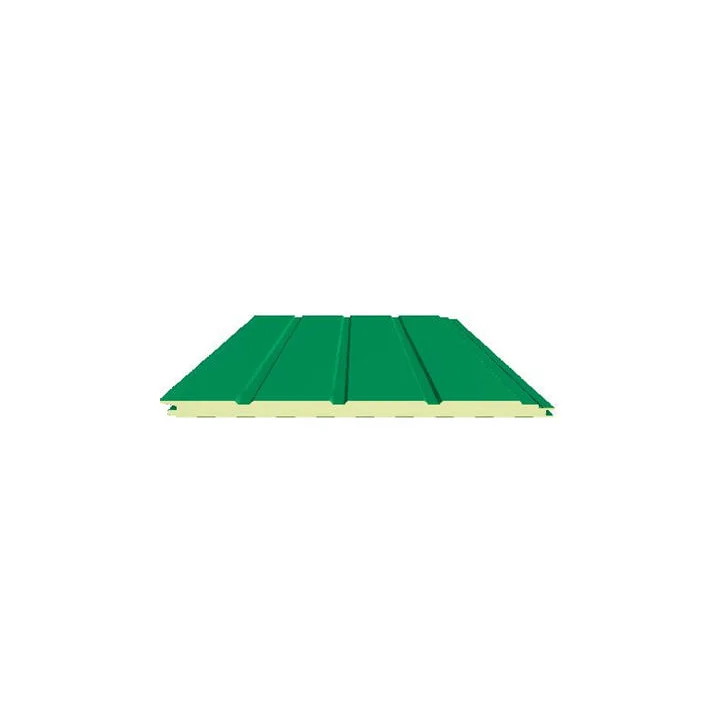

A lot of the big builders as well as businesses in Chile like to work with sandwich panel machines with polyurethane due to the fact that they make building jobs easier and better. And when big things are built, like schools or factories or warehouses, people have to use materials that are both strong and light and can easily fit together. Special panel: sandwich panel machine makes a special kind of panels, like two outer sheets and polyurethane foam in between. This foam is excellent at keeping heat out or in, which means it insulates a building and does not let it get too hot in the summer or too cold in the winter. This is particularly important in Chile because the country contains many different climate zones, ranging from cold mountains to hot deserts.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ