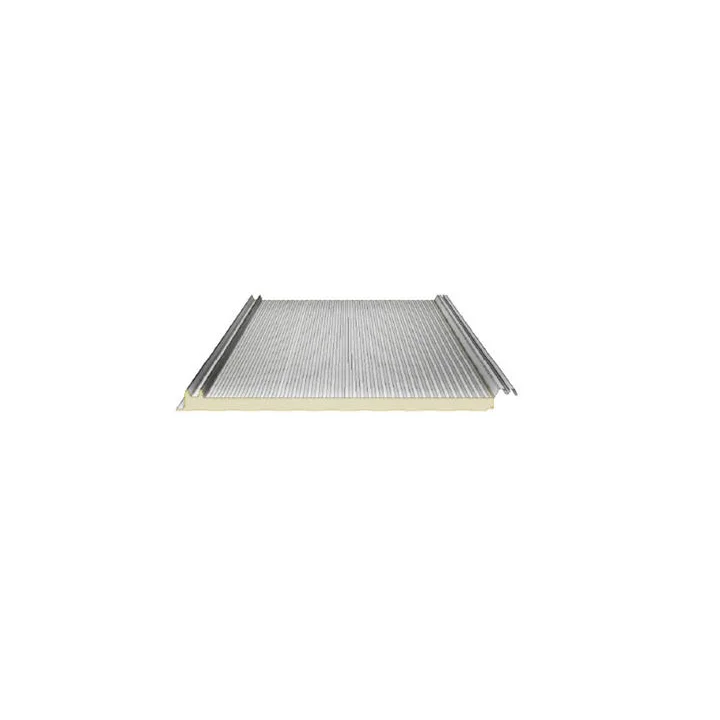

What Makes EPS Sandwich Panel Roll Forming Machines Ideal for Chilean Construction Projects

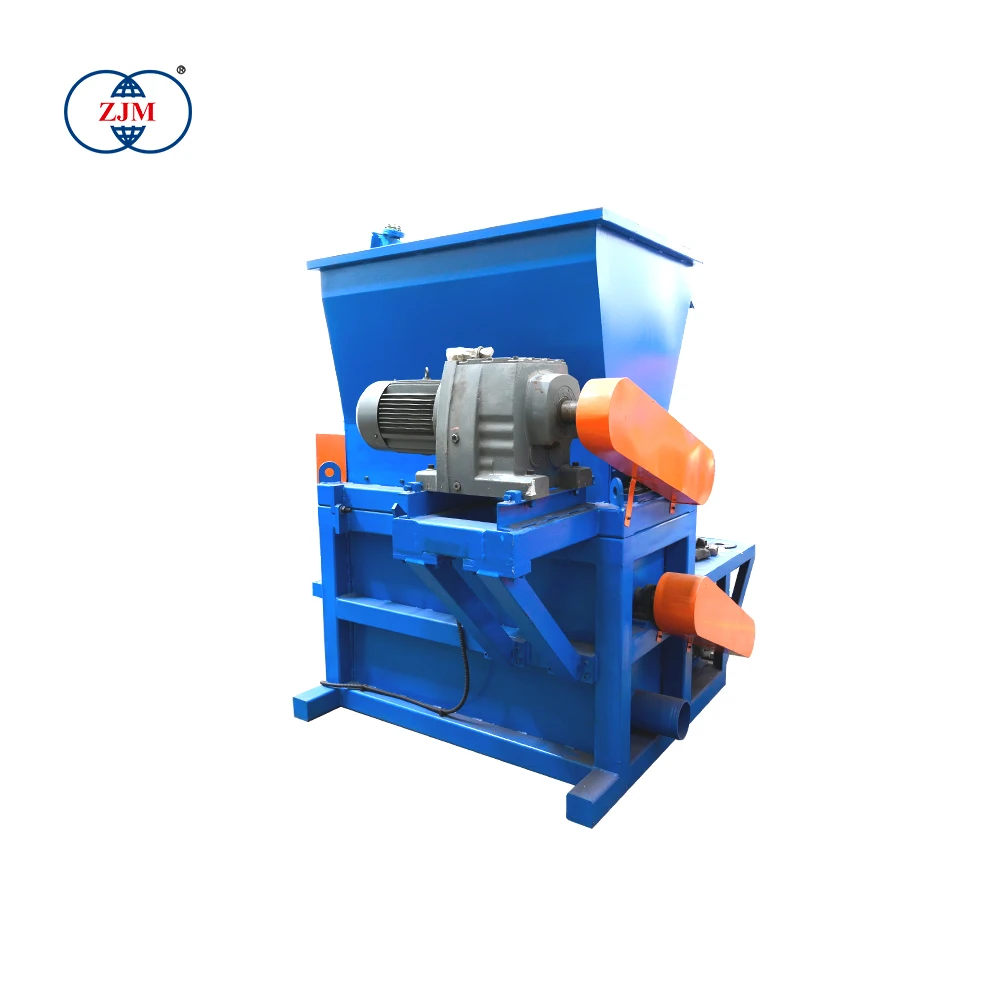

Construction work in Chile is sometimes set back when materials arrive late, or prove hard to find at all. Machines by Zhongji help by allowing companies to make the panels on site or nearby, which can reduce transportation issues. Plus, they can be set up to produce panels of different thicknesses or sizes that correspond with the requirements of a wide variety of projects. For example, a cold climate might require thicker EPS foam for better insulation — the machine can handle that. Builders and workers appreciate this machine for its reliability to run continuously without having to be broken down. That means fewer stops on the job, and that keeps the work moving. Strong, insulated and easy-to-install panels can be produced directly in Chile, which is one of the main reasons why these machines are popular there.

Choosing the right machine is not always simple. There are all sorts of things to consider before picking one up. Zhongji provides several different models, so buyers will want to take a closer look at which option fits their needs. First, decide how many panels you’d like to produce each day. If the number is high, you need a machine that operates quickly and can handle long hours without issue. Some of the smaller machines are effective in less-trafficked areas but may slow down larger makeover projects. Next, consider the machine’s capacity to produce different sizes and thicknesses of panels. It’s important to be able to accommodate whatever the construction job may demand. Zhongji machines are easily changeable and that benefits a lot.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ