What Are the Benefits of Using Sheet Forming Machines in Bolivia?

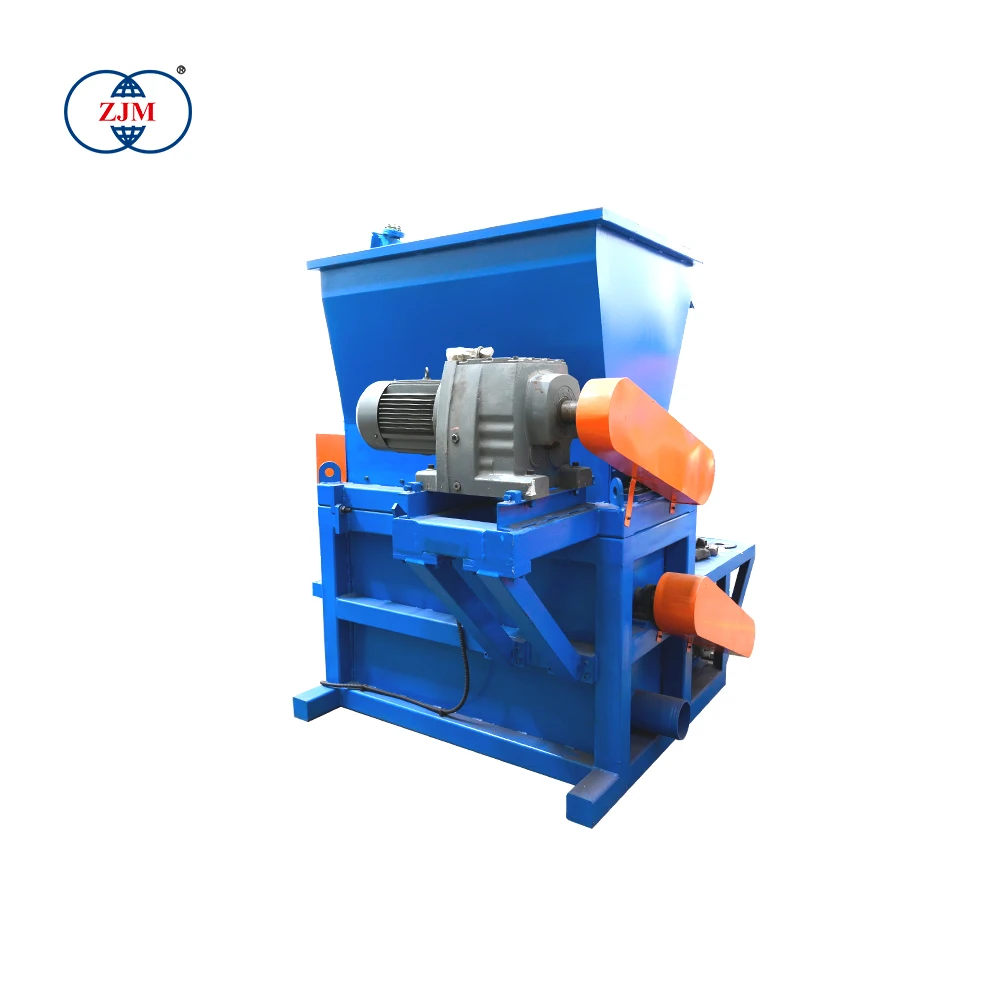

Sheet forming machines are basic requirements for factories, especially in Bolivia. These machines are used to produce a variety of products through various methods, usually from flat material such as metal, plastic or wood. A Sheet Forming Machine produces many items in a quick and easy way. For instance, if you’re producing car parts, a sheet forming machine will cut and bend metal sheets into the right designs. This is a huge time saver because the workers don’t have to do all of that by hand. When machines like those from Zhongji are running your factory is operating smoothly which equals more products out the door in less time for your business. Furthermore, integrating a Heating system for double conveyor can optimize the workflow in production lines.

You’re also going to reduce waste using a sheet forming machine. When materials are cut by hand, scraps might remain that can’t be used. But machines are programmed to cut with blameless precision, so they use the materials more efficiently.” This is not only environmentally responsible, it saves money. You can spend the savings on other important things for your business when you use less material. In Bolivia, which is seeing an expansion in manufacturing, having machines like Zhongji’s can be a huge asset. They can help factories produce more, more efficiently and make products that are high quality. With could efficiency, companies can earn more money and grow.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ