sandwich panel production line usa

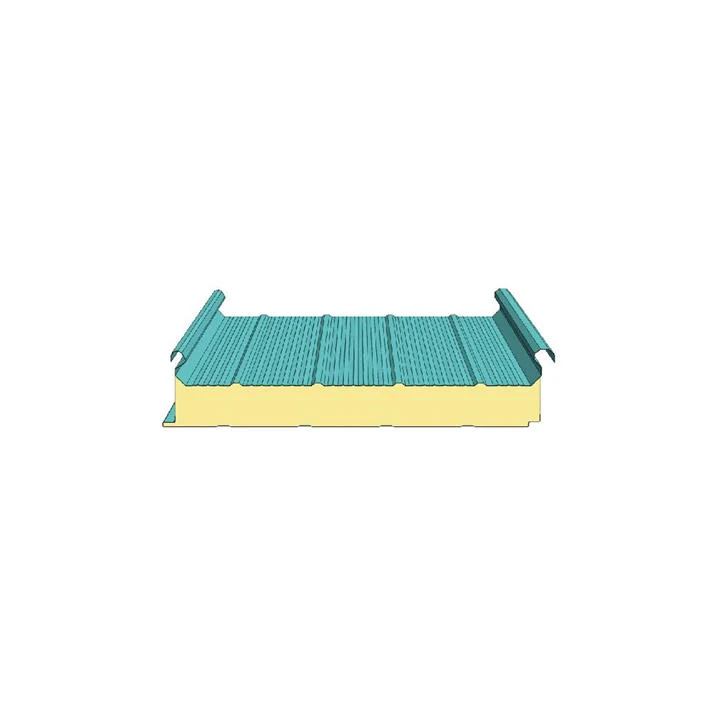

The high-quality sandwich panel production line is composed of hundreds of parts working in unison. First, you’ll need a solid frame to keep everything in place. If the frame wobbles or shifts, the panels won’t be straight or flat. Then, you have the roller station where metal or other materials are rolled flat and formed. The latter part has to be strong and accurate. Quality standard rollers on our zhongji machines allow for SP-7 rockwool/EPS Sandwich panel production line equally distributed pressure and quick setup for different panel sizes. Second, the core (typically foam) should be inserted with precision between metal sheets. And this requires a foam spraying or cutting system that performs quickly and carefully so the foam can fill every gap without voids. The panel will be a poor retainer of heat if the foam is inconsistent. It’s also important to keep your fungus within the right temperature range. Some lines include heating zones to ensure that the glue or bonding will stick. Without proper temperature control, the layers could tear apart later. Speed control is tricky too. The panels could emerge weak, or rough, as well, if the machines are run too fast. If it’s too slow, the company is losing money. The lines of Zhongji make it possible to adjust speed conveniently and well balanced by operators. Good control panels with neat screens make workers see and fix fast what is going on. Plus, safety guards protect workers from moving parts and hot surfaces. In the USA, production lines are often governed by rigid rules about safety and pollution, so equipment must be clean and quiet. What we’re seeing is that lines accompanied by heavy-duty frames, intelligent controls, precise foam systems and safety features create the best panels time after time. These are things that cut waste and reduce cost, which is extremely important for a business

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ