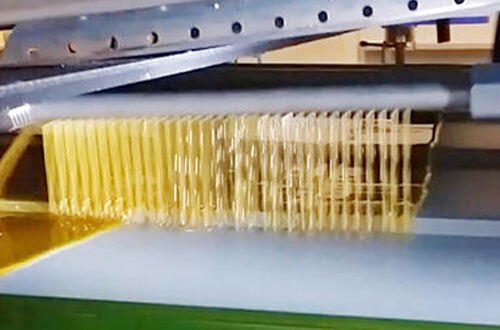

In the Chile, sandwich panels are used in construction. They’re for walls, roofs — even cold storage. The panels are formed of layers of material, including metal, foam or other suitably rigid material. Hence there is an insulating gap between the layers. Special machines are required for companies that make these panels in order to construct them at scale. This is where the sandwich panel machine comes in. Our company Zhongji supply a wide range of quality machinery for this purpose, including the low pressure foaming machine. The machines we provide help companies manufacture sandwich panels very rapidly and with extreme accuracy. They can produce a variety of sizes of panels and different types, so companies can serve their customers.

For companies, selecting the proper equipment for sandwich panel manufacturing is extremely crucial. First, consider how big your operation is. If you’re a beginner, a smaller machine might be best. This can save you some money and a little space. If your business is larger, however, you might require a bigger machine that allows you to make more panels at a time. Next, what types of panels you will want to produce. Various machines can enable you to create various types of panels. For instance, one machine may produce insulated panels and another may concentrate on non-insulated panels. It’s also helpful to make sure you are considering what kind of materials you will work with. Some machines perform better with certain materials, such as the Rockwool glue spraying and PU edge sealing system. Search for reliable and high performing machines. This allows them to run a very long time without wearing out. Zhongji provides you machines that not only work well, but also last! You’ll also want to think about the support and service you could receive once you’ve bought a machine. It’s good to have a company there who can help you if anything goes wrong. Finally, compare prices. You are looking for a machine that will be affordable but not leave you disappointed. Good machinery investment As any reliable business owner will tell you, investing in good quality machinery is the key to your success as a commercial enterprise.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ