What Makes a Sandwich Panel Machine Ideal for Chileu2019s Construction Industry

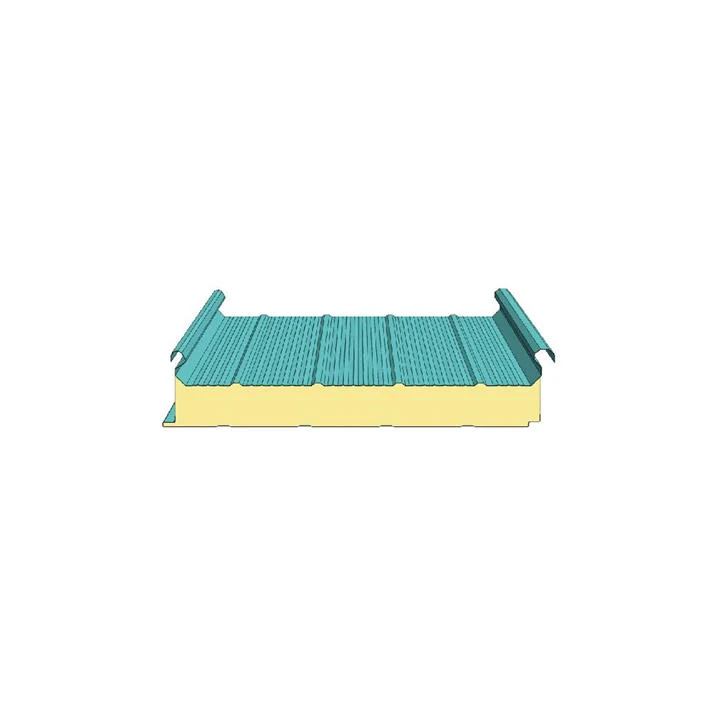

In Chile, the boom in construction is proceeding apace. Strong, fast ways to build walls and roofs are required for lots of buildings, homes and factories. Sandwich panels are ideal for this because they’re light, sturdy and easy to install. The use of a sandwich panel machine allows the panels to be produced quickly and with high quality. But what exactly makes a sandwich panel machine an ideal choice for Chile’s construction requirements? The machine must be versatile in the sense that it can process a variety of materials. In Chile, sandwich panels are made by workers using sheets of metal and insulation material such as foam. The machine should be compatible with these materials and capable of producing panels that help to keep buildings warm — or cool them, which saves energy. Secondly, the machine should be simple to operate and maintain. Parts of Chile may not have full-time, expert technicians at the ready. So a simple machine that doesn’t break as often is very useful. Thirdly, the machine needs to be sturdy and can work for several hours continuously. Building projects in Chile occasionally require many panels, quickly. A machine that runs all day is a tool to help builders make sure they can finish on schedule. We, Zhongji, provide sandwich panel machine that will satisfy all your needs. Our machines are manufactured to grip various materials, and made for durability. They are simple to use, and continue to work even under the harshest of circumstances. This is why Zhongji machines are a clever choice for builders in Chile. Finally, the sandwich panels which are produced by these machines have to conform with Chile’s construction regulations. Zhongji to ensure the machines manufacturing safe, strong and energy-saving panels. This helps Chilean builders make good, long-lasting houses and protect people from changes in the weather.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ