The ultimate guide to understanding sandwich panel production lines in China.

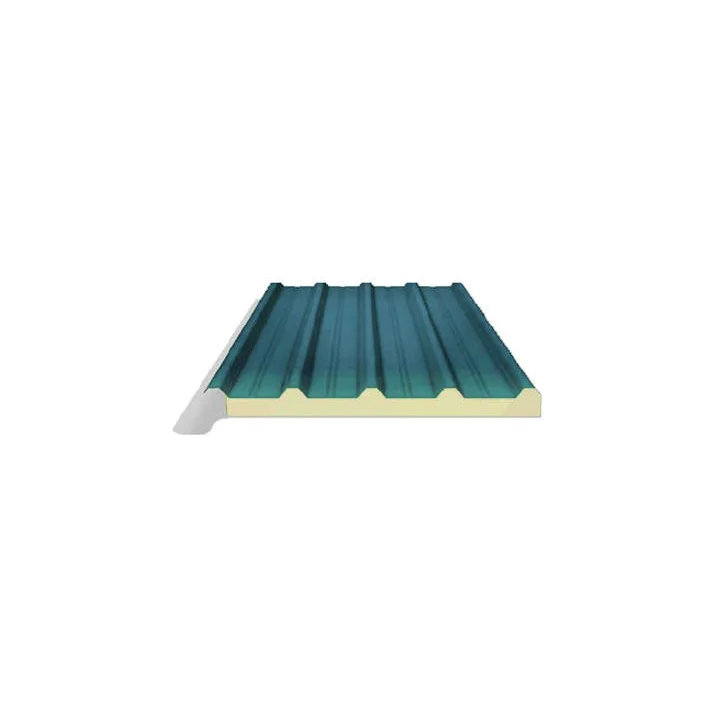

Therefore, sandwich panel? A sandwich panel consists of three layers, two hard outer ones and a soft layer in the middle. Fill is a generic term for all those things that keep the building either warm in winter or cool in summer, which can be made of different materials. For producing sandwich panel, we use a special machine which is named as Sandwich Panel Production Line. The whole thing help in order to make all panel through a proper way by using this machine.

The creation of a sandwich panel begins by getting the raw materials. These will be the ingredients used for making the outer layers and filling of hard and soft. The things that manufacturers need to produce are raw materials such as steel, aluminum and foam, etc. After these materials are gathered they will be processed through the production line.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ