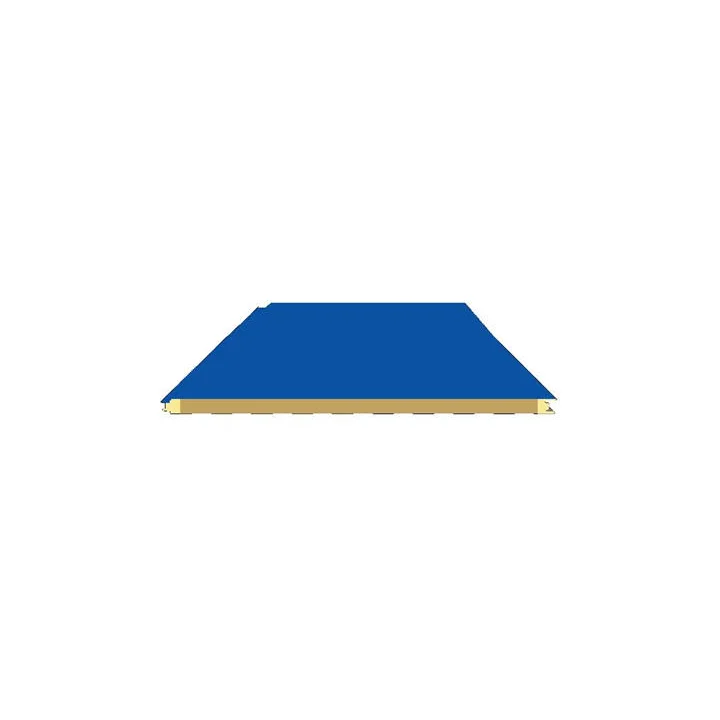

You probably are wondering how much the sandwich panel machine cost you when deciding to buy it for your business. These machines can vary in price greatly depending on several factors. The specific things that you should be considering may include the specifics about what features can I get out of the machine, whats my budget? The difference in pricing can be attributed to the fact that machines are not all created equal.

It can be a bit tricky to sum the price of a sandwich panel machine and there are several core things, which was born with the cost. To begin with, ask your self how many panels the machine can generate in one hour. Certain machines may be faster at producing many panels, while others might take longer. Most are smaller size panels the machine will manufacture. Bigger panels mean the need for more materials and labor, resulting in a higher cost. Finally, the price is also affected by what materials are used to manufacture the machine itself. But when you wonder: how much does it really cost to buy a 3D printer, then apart from price of the machine itself do not forget about that thje tab for its installation? Also, consider how much it will cost to educate your employees on using it as well as for upkeep maintenance the machine over time.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ