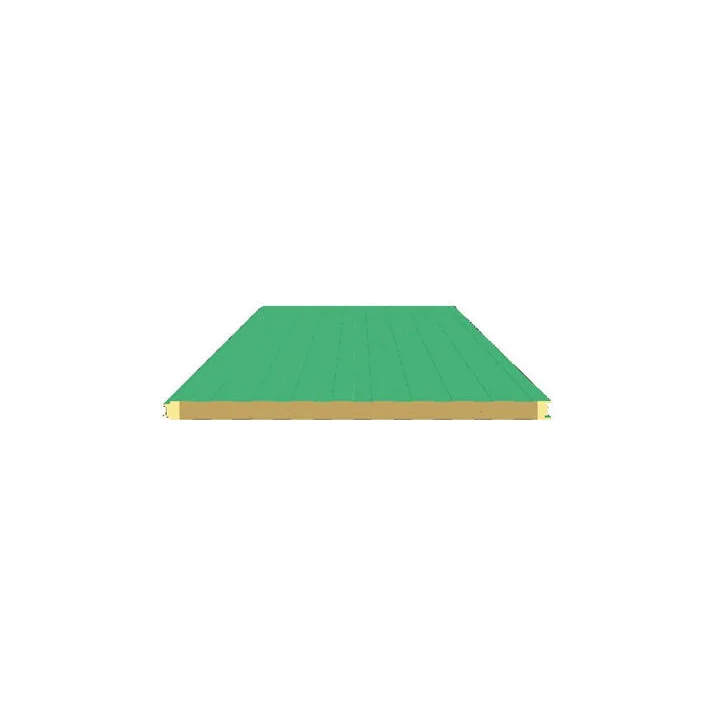

How to Choose the Right PUF Panel Manufacturing Machine in Palestine for Bulk Production

PUF panel machines are not always easy to use. Breakdowns are going to happen sometimes, and knowing what to do can help save time and money. One problem is that the puf panel making machine doesn't do a very good job of mixing materials together. If the mix is incorrect, then the panels will not be strong or insulated. This can occur when the machine parts are dirty or worn. The Zhongji machines are designed to help minimize these issues, but frequent cleaning is crucial. The machine comes to an unexpected stop is another issue. This may be due to power problems or parts jamming. Employees should learn to double-check that speedily. It’s not unheard of for small components like belts or seals to wear down and require replacement. If you let things slide too long, bigger damage can potentially occur. It's a good habit to check the machine everyday before operating it. When you lubricate moving parts, the machine runs smoothly. If the machine gets too hot, it can shatter. Ensure there is some breathing space between the machine and a break in its operation. One prong of keeping the machine whirring is to train workers well. When workers know the machine, they make fewer errors and address small problems before they balloon. Zhongji includes pretty good manuals and the support to do so is available. And keeping a record of maintenance is useful for knowing when to change parts or make repairs. Some people think that the machine is working now, so no maintenance is required, but it's not true. Machines function better and last longer when taken care of. Palestine’s climate can be both dry and damp, which is hard on machinery. Filters and machines can be protected by cleaning them and covering them when not in use. In summary, as long as you take care of your Zhongji PUF panel machine: better panels, fewer problems, and no need for wasting time and money on repairs. It’s work worth doing daily.

When it comes to machine selection, wholesale buyers are usually focused on low prices and strong quality. As for PUF panel making machines, the majority of the customers want to purchase them from Palestine manufacturers. One major reason is that suppliers in Palestine provided a machine compatible with the local market’s needs. These machines are designed to function well with the materials and sizes utilized in Palestine, so that buyers get goods which fit for their precise desires. This saves buyers on cost and time, because they no longer need to change or fix the machines after purchase.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ