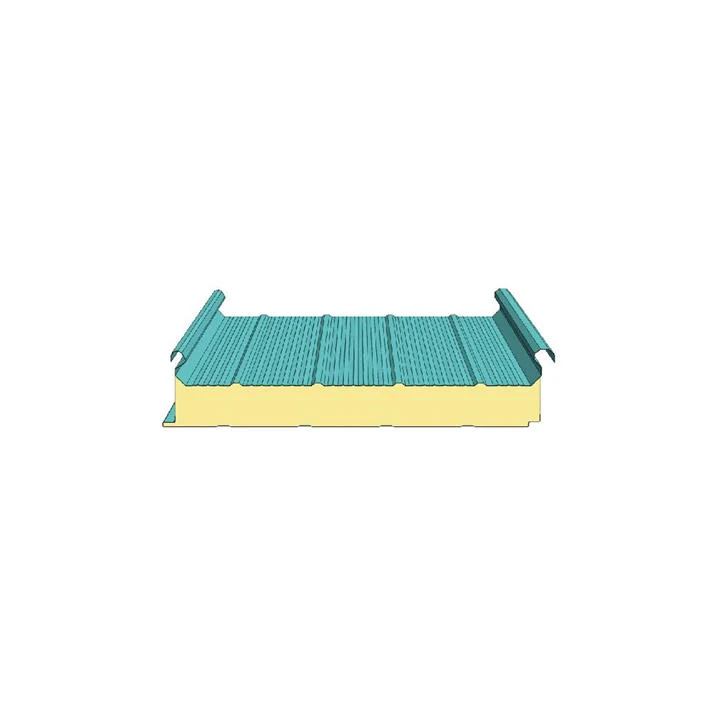

PU sandwich panel press machines are important equipment in the construction industry. They help produce tough, lightweight panels from a foamlike polymer known as polyurethane. These machines press layers of material together to form the kind of panels that are used in walls, roofs and other structures. And in Chile, as construction practices change and people turn to a more rapid and eco-friendly alternative to modern building, these machines are becoming increasingly sought after. Zhongji is committed to providing users in Chile with a variety of excellent PU sandwich panel press machines, so that buyers in Chile can buy better quality machinery.

If you need PU sandwich panel press machines in Chile, then there are lots of choices. First, you can search online. Many then companies, Zhongji included, have websites featuring their machines. Such sites typically contain product information, spec sheets and contact sales information. You can also read reviews from other customers regarding how well the machines work and whether or not they meet their needs. An alternative is to attend fairs and trade exhibitions. These events offer the opportunity to get up close and talk to experts. You can ask questions about the machines’ features and how they’ll help your business. Occasionally you might even score special offers at these events. The local distributors and suppliers are also important. They typically have an array of machines, and they can help you select one that suits your project. They generally are well-versed in the market and can provide good advice.

Ultimately, employers in the construction industry can be promoted by networking with other professionals. Society is full of people who will tell you their horror stories and refer you to reliable brands like Zhongji. As a small business or a major producer, it makes all the difference in how you work when you find the ideal machine. For instance, you might want to consider a Cut-off (shearing) device or a PU/Rock wool sandwich panel line as part of your investment.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ