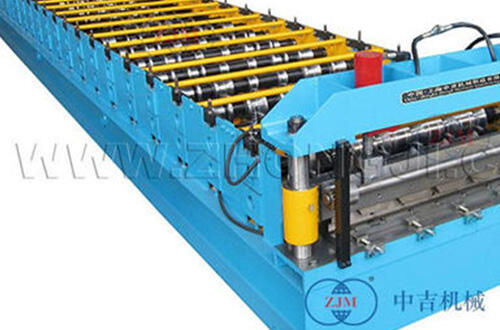

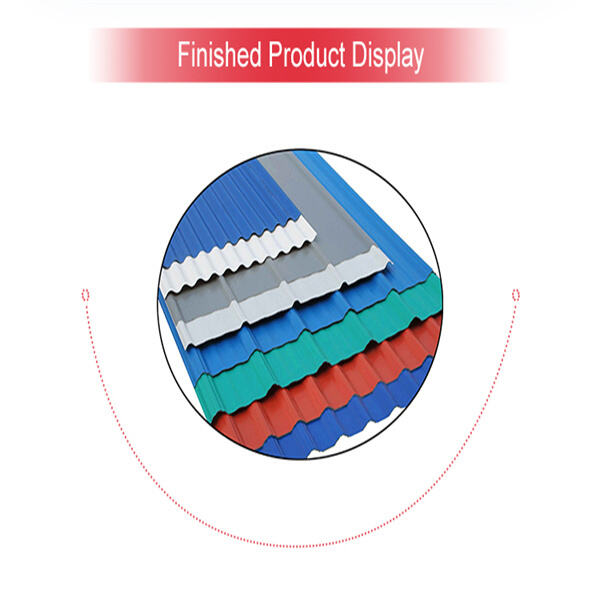

If you’ve ever gazed at shapes like metal pipes, angles or beams and asked yourself how they are made, there are several ways to get your hands on your own custom made metal shapes. One special machine that is used to make these shapes is known as a sandwich panel roll forming machine. Roll formers are a little like magic metal rollers that are able to transform flat sheets of metal into practically any imaginable shape and size.

Roll forming machines are extremely useful in building metallic products because they are known to create shapes with ease and speed. Before these machines were built, workers had to shape things with their hands, which took a long time and was not always accurate. Today, roll forming machines allow firms to produce many metal shapes very quickly.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ