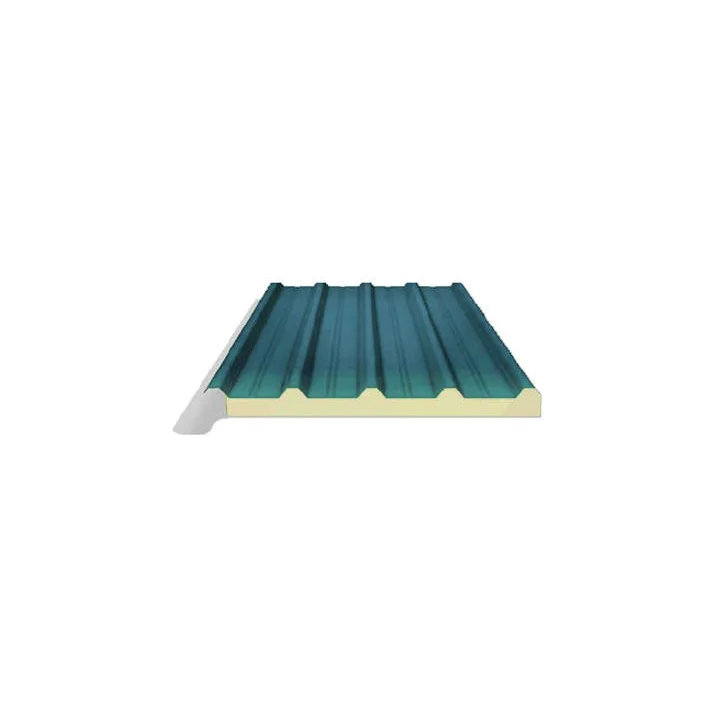

EPS sandwich panel lines are machines for producing special panels widely used in walls and roofs. These panels contain a layer of insulation within them – usually EPS with metal on either side. That makes them strong, light and useful for trapping heat inside buildings. Many builders in Chile require these panels since the weather can be both hot and cold, so buildings need to be safe and comfortable. A reliable EPS sandwich panel line supplier is important for businesses that wish to produce these panels on their own. Zhongji is a company that manufactures these machines and enables builders to obtain what they need in order to build better, as well as faster.

It’s hard to find a reliable EPS sandwich panel line manufacturer in Chile. You need a company that’s attuned to the market and makes machines that operate well in local conditions. First, consider the supplier’s experience. For example, Zhongji have been manufacturing sandwich panel lines for many years, so they know how to build a machine that will last long and do its job well,” Another crucial aspect is the human connection. Sometimes machines need to be fixed or parts replaced fast. If the provider is able to reply quickly, that saves time and money. Also, see if the vendor provides training for your employees. Not all these lines are easy to play, and proper training makes it easier to avoid the mistakes. Some suppliers merely sell machines and don’t provide any support afterward. That can cause problems later. You should also consider price, but don’t just pick the cheapest option without considering the quality. A less expensive machine may break down frequently or make panels that don’t meet specifications. Zhongji manages to strike a balance between price and quality so that you get the kind of machine that performs well and offers longer shelf life. And it’s wise to request references, or even photos and videos of the machines in action at real factories. If possible, see a factory where the machine is in operation. This will give you a sense of how dependable the line is and what to expect.” And consider the delivery and installation situation. A good supplier assists with shipping and puts the machine in place. Sometimes, they even help to get the line going and solve early problems. All of these things make a supplier reliable. It’s not just about buying a machine; it’s about receiving some help to keep your business running smoothly. So, what should you look for in a provider in Chile? These factors enable you to search for the right partner to produce EPS sandwich panel successfully.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ