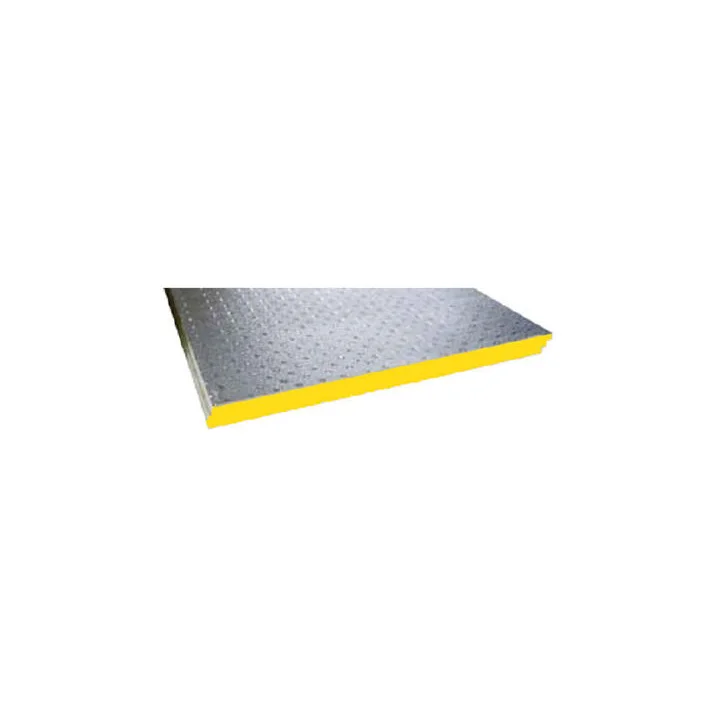

Experience Precision and Efficiency at Our EPS Factory

The truth is, we are extremely proud of our EPS products. What does that mean? It means that we ensure every product is hand-crafted properly. A saying goes, that you can leave the kitchen to cook pastas but not in manufacturing where everything has always to remain equal anytime we produce a product. This is crucial as it implies that when you are acquiring something made from EPS, then be ensured of the fact that it will certainly work and functions perfectly.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ