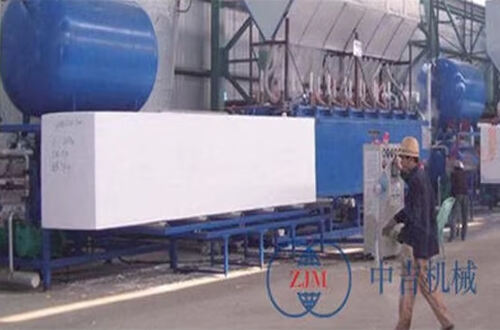

The discontinuous PU sandwich panel lines are equipment for injecting rigid polyurethane (PU) or other type of foam in between skin lamination and forming at one time. These panels consist of two metal sheets sandwiching polyurethane (PU) foam. This foam contributes to making the panels strong, light and good at stopping heat or cold. These lines are very useful in the country of Bolivia, as they help to create panels that can be used in buildings, cold storage spaces and so many other areas. The term “discontinuous” refers to the fact that the machine delivers panels in separate pieces, not one continuous sheet. This production is adaptable and can produce panels of different sizes. Our company,Zhongji has these lines available, they are suitable for Bolivia’s weather, and also can meet the requirements of local manufacturers. Additionally, we offer a low pressure foaming machine that complements the production process.

For market purchasers, it is also very critical to choose a proper discontinuous PU sandwich panel line. For one, these lines enable many panels to be made rapidly yet as individual parts. This is nice in that buyers can order panels to the size they want with no waste. Wholesale buyers require large numbers of panels to sell or install in major projects, so speed and scale options are very important. A simplified design ensures that the zhongji line can be operated and repaired easily, minimizing downtime and maximizing the number of panels produced every day. The machine also conserves materials by dispensing just the right amount of PU foam, ensuring strong, not heavy panels. To wholesale buyers, this translates as nice quality panels that your customers will like and lower raw material costs. The panels made from zhongji’s line are also extremely durable and excellent at retaining heat or cold, which is a significant benefit since the climate in Bolivia can fluctuate. Another consideration is the machine’s energy consumption; it has been designed to minimise its electricity use when working hard, this saving money when producing many panels. Wholesale buyers can rely on the fact that the zhongji line will provide them with speed, quality and a low cost. Occasionally, the buyers change the panel thickness and/or metal sheets used and this machine can do that with minimal difficulty. This flexibility enables wholesale buyers to provide options to customers while remaining competitive. When purchasing a big machine like this one, it’s also worth looking for one that is very durable and easily repaired. Zhongji has a good jump on the vetting process for strong, attainable parts that will minimize any waiting if something breaks. This minimizes losses and keeps business flowing. In brief wholesale users choose zhongji’s discontinuous PU sandwich panel line as a smart option: it matches various requirements, saves you cash and helps you to make great panels in Bolivia.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ