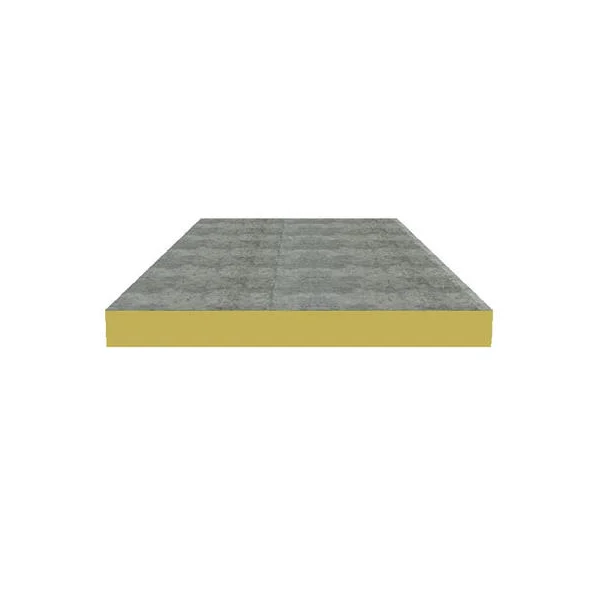

Understanding the Construction of Discontinuous PU Sandwich Panels

Well, one more great thing about the discontinuous PU sandwich panel is that it has a lower weight which makes their handling and installation easier. They are lightweight and so easy to carry around and add when building. This is particularly the case with respect to their being lightweight may stop building adding excess weight- essential, especially if constructing in heavy or weak ground. That attribute could go along way towards ensuring your building lasts to be safe and stable.

In times of extreme weather, then and there discontinuous PU sandwich panels are also very beneficial to keep the internal building climate accommodated. Its inner foam keeps the heat in on cold winter days, along with keeping your cool air inside when trying to beat those hot summer nights. And this extra cost in the short term, when combined with a thermostat that turns off your heating and cooling automatically whenever you are not home can save lot of money over time on your gas bills- which makes these panels economical as well.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ