Quomodo Machinae Plumbi Sandvici Rockwool Augent Qualitatem Producti et Efficientiam

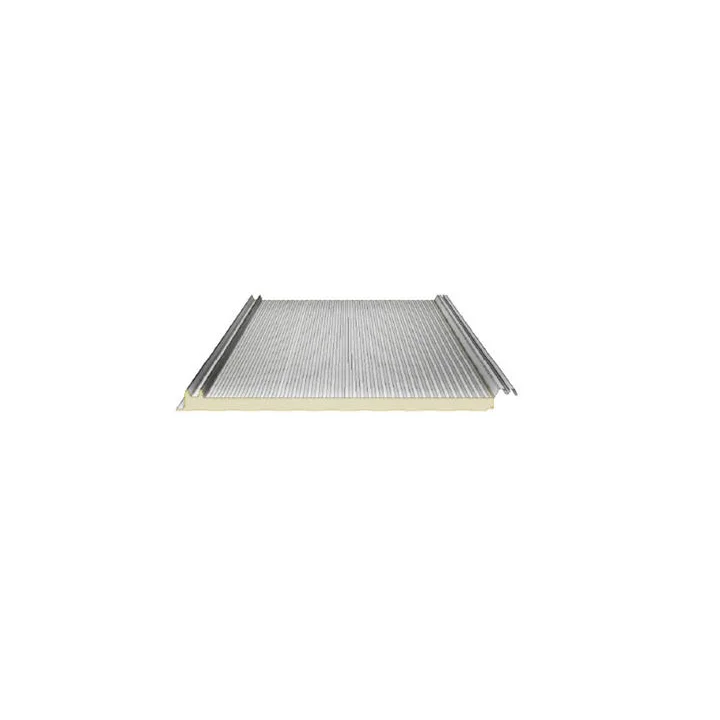

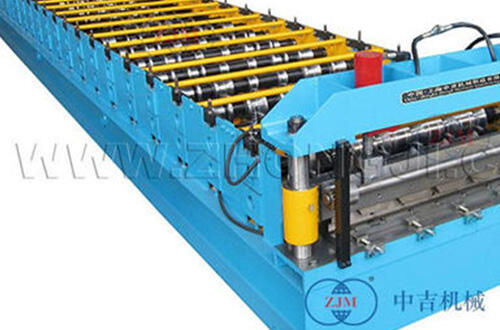

Usus machinae paneles caelibes ex lana silicea meliores facit, qualitate spectata. Exempli gratia, machinae Zhongji adhibentur ad paneles eadem semper magnitudine et crassitudine conficiendos. Ita aedificatores sciunt paneles confidere posse, ut parietibus aut tectis construendis aptentur. Quod attinet ad machinam fractam, ubi paneles varia magnitudine pro stabulo aut toto tecto veniunt, hoc lacunas causat, itaque plura materiae perdit. Porro machina ita operatur, ut lana silicea intra paneles valida maneat, nulla illa frangente. Insulatio valida domum calidam aut frigidam reddit, prout tempus exterius postulet. Velocitas etiam Zhongji magna res est. Machinae societatis multos paneles celeriter efficiunt, celeriterque sine erroribus replicant. Fabricae eas utuntur in Chile ad plures paneles in die faciendos et citius plura mandata perficienda quam antea. Etiam efficit, ut operarii occupati sint nec otiose sedentes videantur, dum machina non recte operans reficienda est. Praeterea, automatio vera mutationis causa est machinarum: cum machina per se operari potest et sub pressione, temperatura, velocitatisque mutatione, errores humani minuuntur, et quae facile rejiciuntur; sic machinae emendi sunt vilitates et paneles quoque. Aliquae machinae etiam configurationes sine difficultate mutare possunt, ita ut cito unum typum panellis ad alium mutandum expediat, prout opus postulet. Itaque non solum est machina panellum caelibem ex lana silicea; totam aedificandi industriam in Chile validiorem, velociorem, sapientioremque reddit. Machinae Zhongji certae sunt bene designari et technologiam totum mundum mutare posse, non tantum societatibus ad plura quaestus facienda, sed etiam loca habitandi et fabricas creanda, quibus homines vivant.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ