Quomodo EPS Machinae Moulding Block Efficienciam in Fabricatione Espumae EPS Meliorant

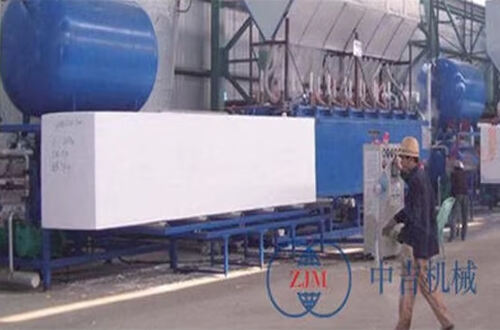

Hodie quaedam EPS formae caelatura machinarum humanam partem minimam poscunt, in praeventione errorum secantibus iuvant, et tutiora sunt quam unquam. Exempli gratia, machina ipse temperaturam et pressionem regulet, semper cuneos spumosos rectissimos producens. Quod significat operarios non debere machinam continuo inspicere, itaque alio negotio facilius incumbere possunt. Societas tibi qualitatem bene praebet eps caelatura machinam, quae facile utens est et efficax. Et haec machina formandi block adiuva fabricantes spumae melius facere munera sua et plura efficere. Cum machinis praebitis, societates tempus salvare possunt, minimizando inutilia et producendo firmos caelos spumae qui diutius durant. Quod rursus simpliciorem reddit et totius processus manufacturandi impensas minuit. In conclusionem, machina formatura caeli EPS viam praebet optimam ad productionem augendam quo modo caeli spumae EPS fiant. Operam minuunt, firmam merchemdiam producunt et pecuniam conservant. Electio rectae machinae, ut illae ab ea, omnem differentiam facere potest cuique operatori in industria manufacturandi spumae EPS.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ