How to Maximize Efficiency Using Sandwich Roof Panel Machines in Bolivia

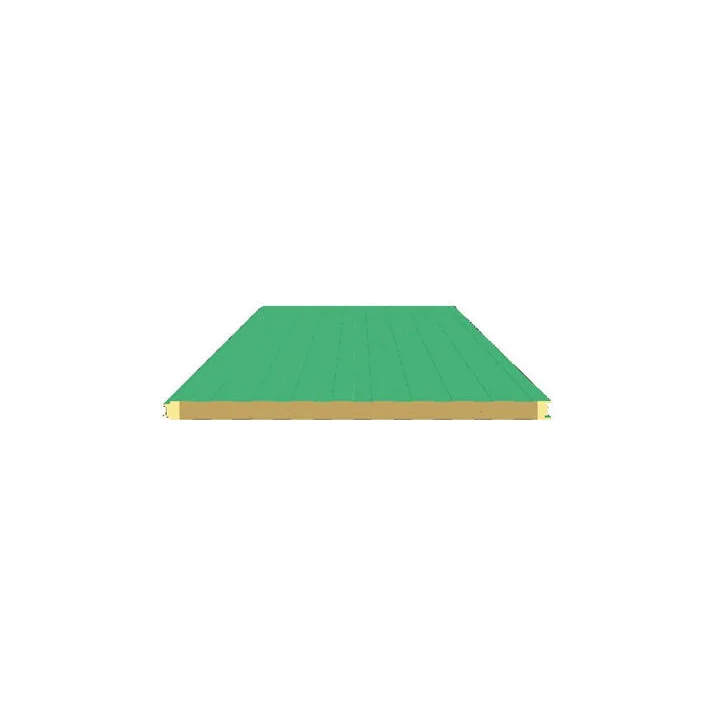

Some intelligent steps are required to get the best from sandwich roof panel machines. One, workers should learn how to actually run the machines. While zhongji makes user-friendly machines, training also can help prevent errors that slow down work or produce bad panels. If people understand the settings and parts, they can fix whatever small problems come up quickly and not stop making panels. For instance, dialing in the thickness of insulation or metal sheets at the outset will save time later; panels won’t have to be redone. Another piece of advice is to make sure the machines are kept clean and oiled. Dust and grime can slow down machines or even stop them altogether. In Bolivia, which sees a lot of dust, such routine cleaning goes a long way to ensuring machines last longer and work faster. Another reason: good materials allow the machines to make better panels. Zhongji’s machines are compatible with a variety of insulation types, but choosing the right one for their region and project plays a large role. If taken with cheap or wrong materials, panels can be weak or unable to retain heat which is a waste of time and money. Also helpful is planning the work out before you begin. If the team knows how many panels they’ll need, and in what sizes, they can program the machine to make a given number of every size of composite panel automatically. So no more wasting time constantly adjusting settings. For instance, producing all the panels for one side of a building before turning to another side is an economies-of-scale measure. Machines can sometimes run faster, but pushing them too hard can lead to errors or damage. It’s best to strike some balance between speed and quality. And having a stockpile of spare parts — such as rollers or belts — means that when something breaks, repairs are fast. This prevents long bottlenecks that slow down the entire project. And last but not least, zhongji’s team can provide advice and support. When employees have questions or run into problems, talking to experts can resolve issues quickly, and work proceeds. Because when machines perform well, builders can complete the job at hand faster and customers can enjoy a quality-built roof long into the future. So, paying attention to details and working smartly with sandwich roof panel machines matters most in the constructive work of Bolivia.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ