How Sandwich Panel Machines Improve Construction Efficiency in Chile

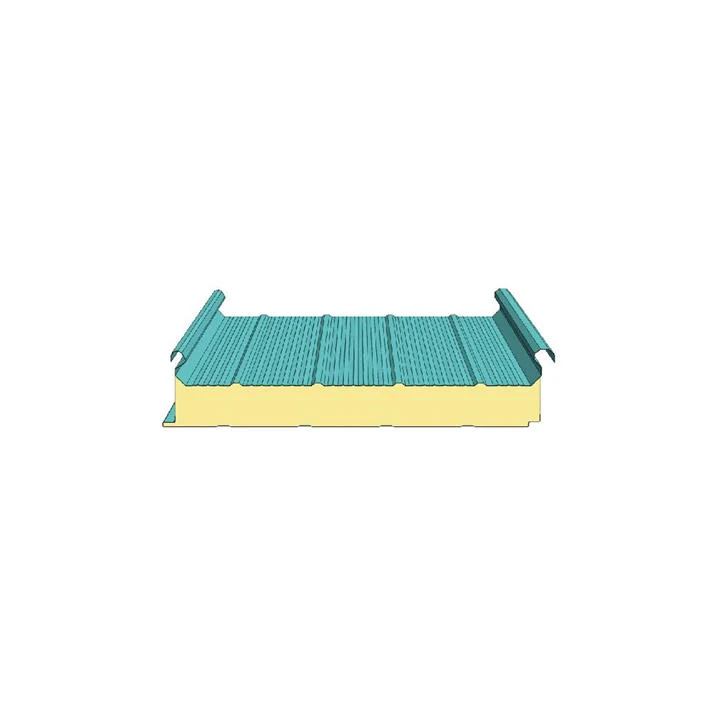

You Might Need In Chile The Use of Sandwich Panel Machines Are Blooming Sandwich panel machines are main thing the making everyone work faster and easy in construction world, in Chile. Prior to these machines, workers had to create walls and roofs one element at a time, a painstaking process. With sandwich panel machines it’s possible to produce a lot of panels in short time. For instance, zhongji’s machines have the feature of continuous production without stopping and can produce long panels. This is a way to help builders receive materials on time, preventing the waiting. And panels produced by machines are always a uniform size and shape. That means when workers come to a construction site, they can install the panels quickly without cutting or fastening much of anything. It saves hours or even a few days on large projects. Another way in which these machines are a boon is that they cut down mistakes. There can be errors in manual work; panels may not be entirely uniform, or weak spots may form. Machines sidestep that problem by creating each panel according to exact rules. Zhongji machines take exact orders to ensure that the thickness and insulation are perfect every time, which is similar to using the Rockwool glue spraying and PU edge sealing system. That makes those buildings safer and more comfortable. And machine-made sandwich panels are both lighter and strong. This makes it easier for workers to transport and install them more quickly without the use of massive cranes. It is also cheaper to ship, as more panels can be packed on one truck. Occasionally weather can delay the process of building work, so factory-made panels remain protected until required. This way, construction could continue even in rain or extreme heat. So the whole construction process is more fluid. Finally, machines like zhongji machines could help factories make various kinds of panels. Some of them keep heat in, others are fire- or sound-resistant. Builders in Chile can choose the right panels for each project, making home, office or factory better. It’s a versatility that has quickened construction times and provided builders with greater options. In the final analysis, sandwich panel machines represent a fundamental change in how buildings are created – all of which makes construction faster, easier and stronger.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ