Foam is fun to make things from! This is a great one for making all types of plushies, cuddly pillows and warm elbow pads. However, did you know that foam is also used to build homes or buildings? That’s right! Foam, pound for bounce, is one of the best materials you can use in construction.

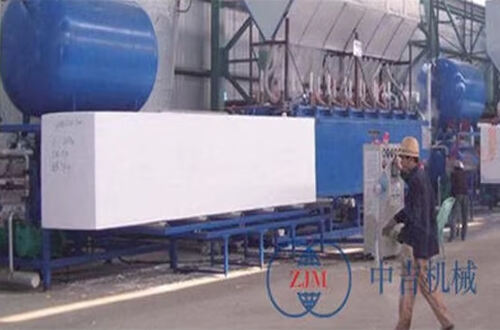

A PU panel machine is specific hardware that allows people to produce durable foam panels. Massive, interlocking foam panels that can be assembled like puzzle pieces to form walls and roofs for houses or other buildings. They provide a great purpose keeping our homes warm during the cold winter months and cool in summer. This keeps the house comfortable inside, no matter what is going on out of doors.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ