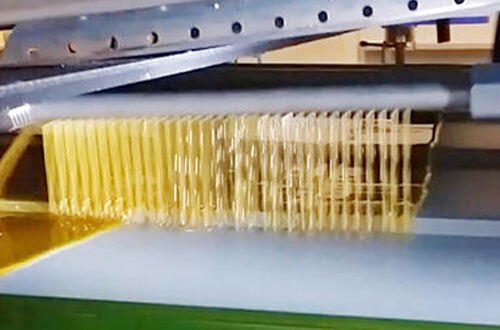

When considering high pressure polyurethane foaming machines in Bolivia, there are many users who always want to have tools that works at a faster rate produces the strongest foam. Polyurethane foam is used in a variety of ways — for furniture, insulation, car parts. Machines that perform high pressure foaming scrunches chemicals together at a very fast pace to form tough foam which continues to be in shape for longer periods. Zhongji’s machines are ones that many businesses believe in, because they do the work and stop them from taking too much time. These machines are not only powerful and large but also intelligent in how they blend and spray the foam. This helps companies in Bolivia to manufacture more, and keep customers satisfied. But it’s not always easy to decide on the right machine, because there are so many factors to consider. Let’s discuss how to choose the best machine, and what features these machines have, that Central Tech teaches kids on how to repair both as well.

It can get confusing when selecting a high pressure polyurethane foaming machine for wholesale. There are also many choices, and not all machines are suitable for every business. First, consider how much foam you’ll want to be making every day. And if your business needs to print a lot, you want a machine that works quickly and isn’t constantly breaking down. Zhongji washer machines are heavy duty for large scale and can operate all day. Next is to look the mixing system of the machine. Quality machines mix the chemicals thoroughly for foam that is smooth and strong. Some machines offer adjustable pressure, allowing you to adjust how dense the foam is. That matters if you produce different products. And, too, seek machines that are easy to use. Some machines are controlled by nothing more than a few buttons on the front; others feature sophisticated screens. In wholesale businesses, the best thing is to have machines that workers can learn quickly because many people use them. Another one, of course, is parts and service. When machines go down, you want them up and running at full speed as quickly as possible. Zhongji provides parts that are simple to procure and labor who can assist in Bolivia. Don’t forget energy use. Machines that consume less power cost less to run, but they still need to perform well. Size matters as well — some factories are small and require already the needs compact machines. Finally, confer with other businesses or your experts. Trying to figure out what will work best in Bolivia can give you better ammunition. Purchasing the right machine is about considering not just what your company needs now, but also what you want it to be in the future. You might also want to look into a low pressure foaming machine as an alternative depending on your production needs.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ