Why Wholesale EPS Sandwich Panel Production Machines Are Trending in Chilean Marke

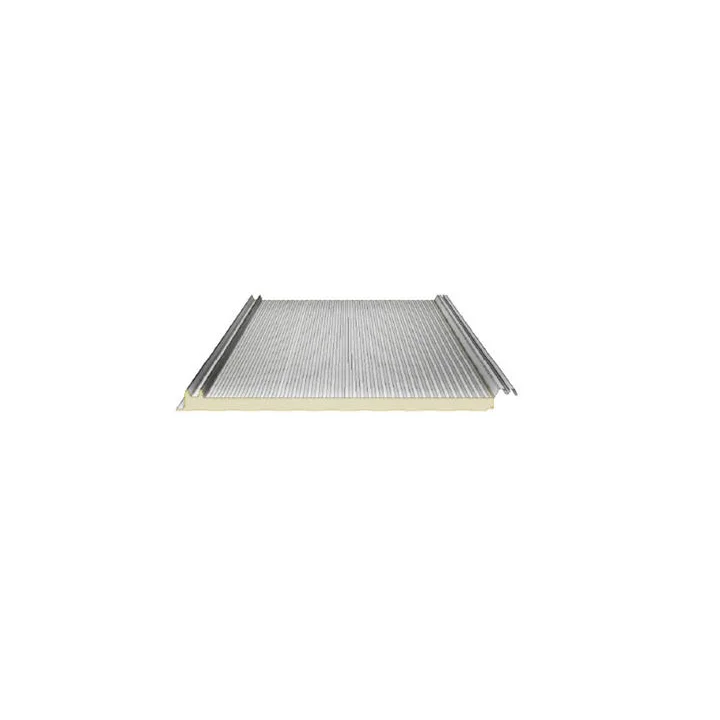

In Chile, lots of businesses are beginning to purchase the EPS sandwich panel production device in big quantities. This is called buying wholesale. Wholesale machines are popular in the Chilean market for good reason. First of all, purchasing machines wholesale is going to save a lot of money. When businesses buy lots of machines at once, the price for each machine typically falls. This helps Chile builders and manufacturers get the very high quality machines from zhongji at a low price. Second, Chile is bustling with growth, new buildings, factories, homes are being built daily. Which means a lot of EPS sandwich panels are in need on the market. Companies are looking to have ”lots and lots of machines” so they can manufacture panels at a high enough rate to flesh out the needs of new buildings. Purchasing wholesale enables them to quickly acquire enough machines.” Third, purchase in bulk simplifies the act of beginning or expanding a business. Smaller companies can band together to purchase machines in bulk, and thus have the power to compete with larger businesses. This makes the entire market in Chile stronger and more successful.” Fourth, zhongji machines are renowned for their reliability and user friendliness. When companies are investing in many machines, they want to know the machines will last and not break down frequently. Zhongji’s equipment has decent quality, therefore they are an intelligent choice to wholesale buyers in Chile. Finally, the government and local builders are promoting the use of EPS sandwich panels due to their energy-saving and security-related features. Purchasing machines in wholesale can serve this demand faster. In summary, in Chile the wholesale EPS sandwich panel production machine is very popular because of economy, high artistry and quality machinery from a reputable company like zhongji. This shift makes Chile’s construction industry, already one of the country’s fastest growing economic sectors, considerably faster and stronger.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ