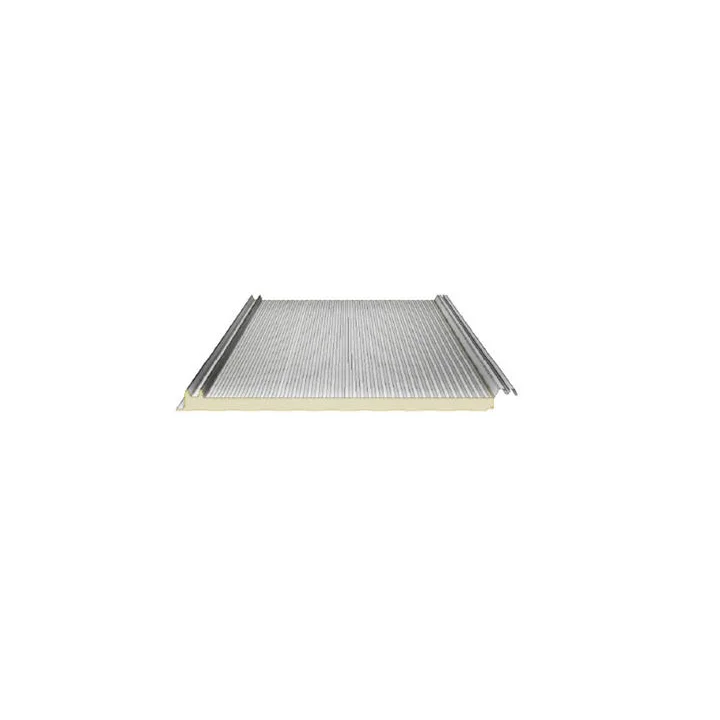

EPS sandwich panels are used as wall surface roofing system material for steel frameworks, such as storage facility, gymnasium, workshop, medical facility, dining room, kitchen area and so on. And if you want to ensure that you have a great EPS sandwich panel production line. Zhongji provides the devices to produce these panels in high speed and high quality. The machines function like a chain, and each section does specific work like reducing, pushing and signing up with the products. If you want to create a great deal of long-lasting, great looking panels, using a resilient assembly line can be a great option. It reduces time, and ensures the panels are perfect when it comes time to develop houses, workplaces or cold storage space spaces.

Choosing the proper eps sandwich panel machine is not a simple task. There’s a lot to consider before you take it. First, consider how many panels you want to produce per day. If you need many, panels quickly, you don’t want a machine that will run fast until it stops working. Second, the machine should be user-friendly. It is easier fo users to use our product. It is also easy to operate so workers can learn quickly and do better work. Our product has different sizes. Not all lines have the capacity to run various sizes, but our system can be modified to handle different widths and thicknesses. And our cheap machines can have a lot of fixing needed, or use more electricity. Finally, see if the company assists with setting up your system on site and solving problems. These are the things you should know when looking for proper machine.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ