What are the benefits of using an EPS foam molding machine?

In addition, RIGID foam molding machines are constructed with materials efficient to minimize waste and enable manufacturers to maximize their resources and save costs. The Exact control and adjustment capabilities these machines provide allow companies to manufacture foam products at optimal yields with the least amount of scrap / regrind, resulting in better overall productivity and profitability.

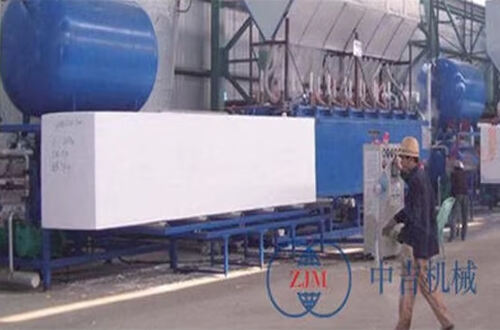

The Zhongji eps foam cutter moulding machines, which include motor type and normal type with the capacity ranging from1000kw12000kw are able to satisfy the requirements of different customers. Centered around European craftsmanship and quality, our machines are no nonsense delivery nothing short of industrial grade. Whether you are a small business or a professional industrial plant, our EPS foam molding machines are an affordable and efficient solution to upgrading your production capabilities with many other productivity-enhancing features.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ