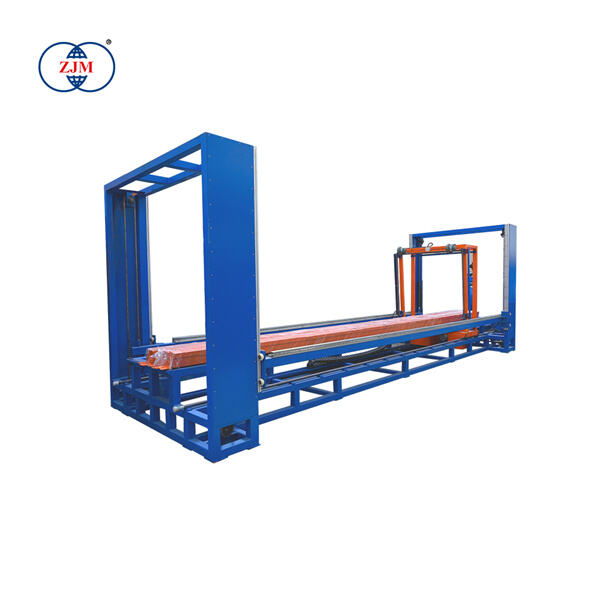

I bet you did not know, there are machines that can cut very hard stuff like foam, plastic or rubber shape according to design more precisely. So these machines are an EPS cutting machine which means the Expanded Polystyrene Cutting Machine. Factories use it to make a plethora of items ranging from boxes for shipping, insulation in buildings and even as flotation devices on boats that keep them above water.

Most of these machines will get the job done because they are using cutting-edge technology that gives you very precise cuts — one way to describe this tech is through its name: a computer numerical controller. In fact, some even use lasers — the highest power light beams known to man- for cutting entire structures with pinpoint accurate. With this advanced cutting and they are able to deliver any form or shape of the design which is very hard or nearly in possible by hand through machine.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ