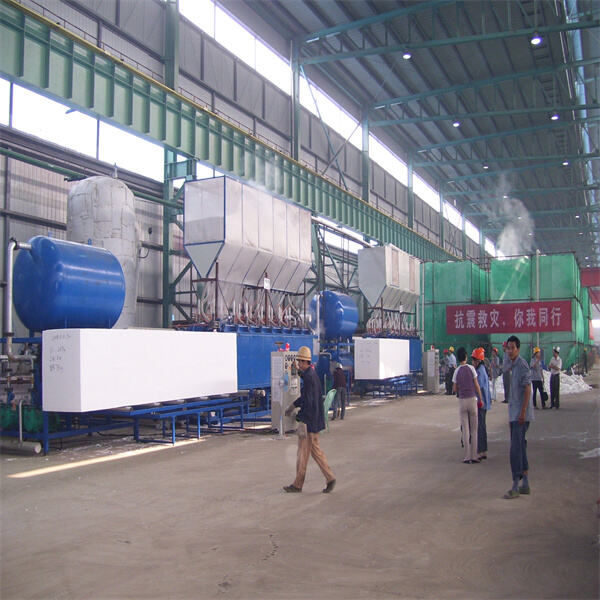

Years ago, people would use large chunks of foam to cushion their items. This foam was responsible for keeping things in tact during shipping and moving. Fortunately, however there exists a wonder machine known as the EPS block moulding machine which is redefining how we pack and protect our stuff!

An EPS block moulding machine is a large and high powered device that makes numerous foam blocks simultaneously. It's like a huge cookie cutter cutting the foam into rectangles! The foam blocks it produces is super lightweight so its easy to carry around. But they are so strong that could take care of as important items secure. This is why people use zhongji eps block molding machine to pack a variety of items like TVs, refrigerators and also some fragile things that can break easily.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ