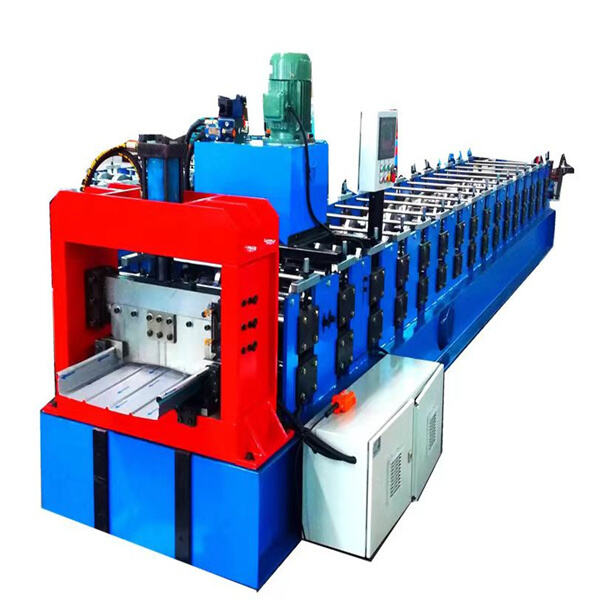

Cold roll forming machines are some really neat machines that make all kinds of great stuff out of metal. They are sort of like magic machines that turn a humble lump of metal into something great.” Read on for a better understanding of these machines and what they are capable of!

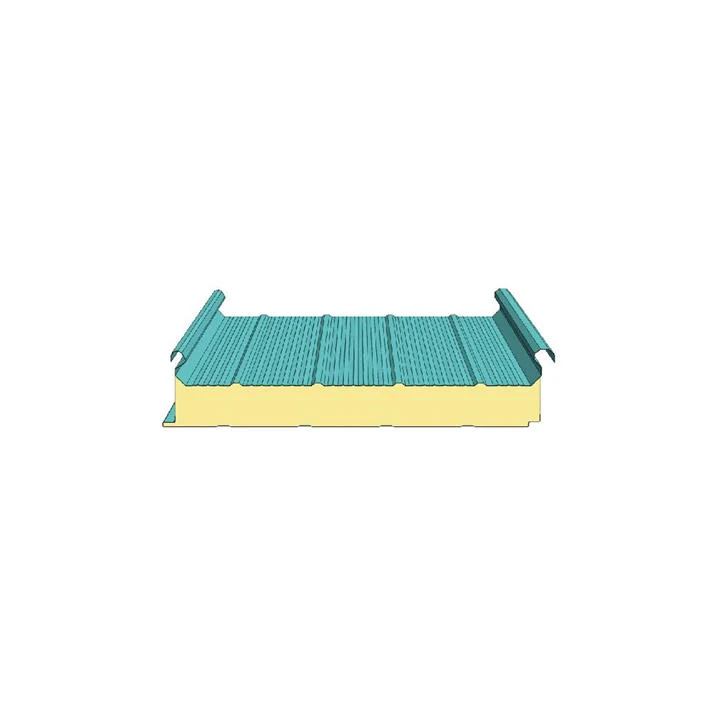

Cold roll forming machines are large machines used to bend metal into various shapes and sizes. They also play a key role in the production of metal products. It’s a process known as metal fabrication, where metal is cut, bent and shaped into wonderful things. They work by running special rollers over the metal, bending it but not melting it. That's why they're known as "cold" roll formers.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ