- Главная страница

- О Нас

-

Линия По Производству Сэндвич-Панелей

-

Линия Чистых Помещений Для Стеновых Панелей

- Гидравлический Размотчик

- Устройство Выравнивания

- Машина Для Профилирования Листов В Короб

- Система Нанесения Клея На Сэндвич-Панели

- Машина Для Нанесения Клея На Листы Из Стекломагниевого Композита

- Система Транспортировки И Поворота

- Высоконапорная Машина

- Машина Для Штабелирования

- Упаковочная Машина

- Машина Для Формования Кильного Листа

- Линия Производства Холодильных Положений

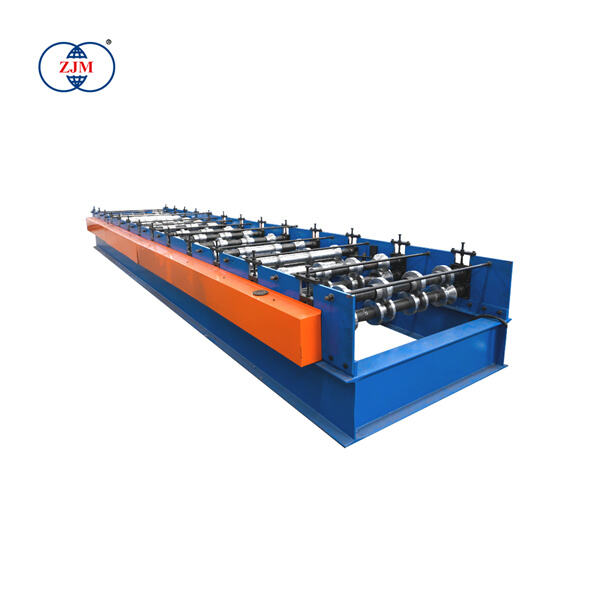

- Машина Для Формования Проката

- Линия Производства ПУ-Сэндвич-Панелей

-

Линия Панелей С ПУ/Базальтовой Ватой

- Гидравлический Размотчик

- Предварительный Нагрев

- Машина Для ПУ-Пены Искусственного Газона

- Высоконапорная Машина Для ПУ-Пены

- Портал Для Пенополимеров С Колебанием Миксерной Головки

- Двухленточный Конвейер

- Поперечный резак с ленточной пилой и дисковой пилой для перекрывающейся резки панелей крыши

- Система Охлаждения

- Стекер

- Упаковочный автомат

- Автоматическая система подачи каменной ваты

- Устройство отрезки (гильотины)

- Устройство резки и обрезки с системой переработки

- Система распыления клея для каменной ваты и ПУ-герметизации кромок

- Система нагрева для двойного конвейера

- машина для низкого давления пенообразования

- Линия производства сэндвич-панелей из каменной ваты/EPS

- Разматывающая машина

- Машина для пенения полиуретана высокого/низкого давления

- Машина Для Нанесения Клея

-

Линия Чистых Помещений Для Стеновых Панелей

- Серия EPS/EPP

- Новости

- Случай Производительности

- Скачать

- Контакт

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ