बोलिभियामा, राम्रो बनाउन र सुधार गर्न खोज्ने व्यवसायहरूको कमी कहिल्यै हुँदैन। यसलाई गर्ने एक तरिका हो स्याण्डविच प्यानल फर्मिङ मेसिन प्रयोग गर्नु। यी मेसिनहरूलाई निर्माण र निर्माणमा अन्यत्र फिट हुने, मजबुत, हल्का प्यानलहरू बनाउन प्रयोग गर्न सकिन्छ। प्यानल स्याण्डविचलाई भित्ता, छानो र भवनका अन्य घटकहरूको रूपमा प्रयोग गर्ने क्षमताका कारण बोलिभियामा बढ्दो माग छ। यी प्यानलहरूलाई उल्लेखनीय गति र लागत स्तरमा उत्पादन गर्न कम्पनीहरूले मात्र राम्रो मेसिनको धन्यवादमा सक्षम हुनेछन्। उद्योगमा झोंजी एक विश्वसनीय ब्रान्ड हो, र तिनीहरूका मेसिनहरू मध्ये तपाईं आफ्नो कम्पनीका लागि उपयुक्त मेसिन फेला पार्न सक्नुहुन्छ, सहित ३D पैनल मशीन संयोजन गर्ने .

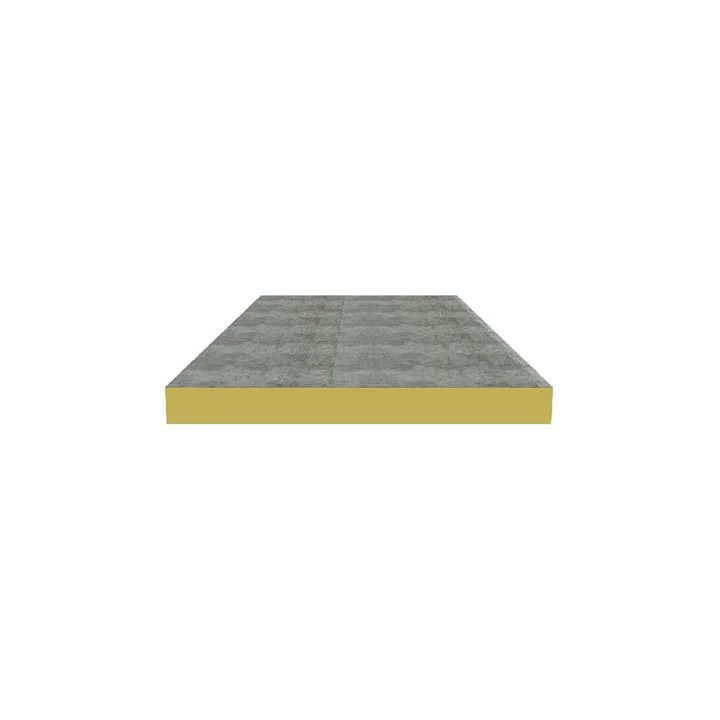

तपाईंको व्यवसायका लागि उपयुक्त सैंडविच प्यानल बनाउने मेसिन छान्दा तपाईंले केही कुराहरूमा ध्यान दिनुपर्दछ। सुरुका लागि, तपाईंको कार्यक्षेत्रको दायराको बारेमा विचार गर्नुहोस्। एउटा सानो व्यवसायलाई ठूलो मेसिनको आवश्यकता नपर्न सक्छ, जबकि ठूलो कम्पनीलाई धेरै अर्डर पूरा गर्ने क्षमताको आवश्यकता हुन्छ। अर्को कारक जसलाई विचार गर्नुपर्छ, तपाईंले बनाउन चाहनुहुने प्यानलहरूको प्रकार हो। विभिन्न मेसिनहरूले विभिन्न प्रकारका प्यानलहरूलाई सम्बोधन गर्छन्, त्यसैले तपाईंले आफ्नो उद्देश्यअनुसारको मेसिन छान्नुहोस्। गुणस्तर पनि महत्वपूर्ण छ। तपाईंलाई निर्माण मापदण्डहरू पूरा गर्ने मजबूत, टिकाउ प्यानलहरू बनाउन सक्ने मेसिनको आवश्यकता छ। झोङ्जी मेसिनहरूको गुणस्तर अतुलनीय छ र त्यसैले बोलिभियाका धेरै कम्पनीहरूले तिनीहरूमा भरोसा गर्छन्, तिनीहरूको सहित ICF र EPS डेक फर सिस्टम .

लामो पुरुषहरूका लागि

लामो पुरुषहरूका लागि

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ