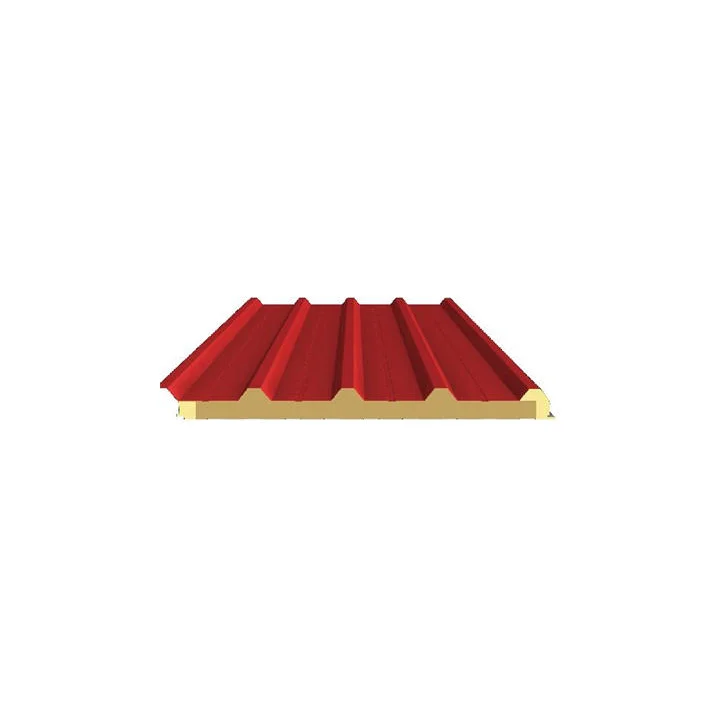

Panes sandwich machinis specialibus conficiuntur. Hi panes sunt materiae speciales quas homines ad tantas res faciendas utuntur, sicut aedificia, domos et apartamenta. Hae machinae sunt summe necessariae, quoniam eas ad creationem talium panelum facile et cito iuvant. Ubi non praebentur, eos cum multo labore et tempore fieri necesse est.

Omnes panes sandwich olim facti erant per manus hominum solas, quod erat processus longus et difficilis. Hi manu laboriose adfixi debebantur multis variisque materialibus ut ferro et schuma, deinde relicti erant ut omnia siccarentur. Et interdum, haec expectatio dies vel, quod deterius, septimanas exigebat! Nunc tamen homines hos panes multo citius quam unquam antea producere possunt cum machinis panelium sandwich. Materialia a machinis cito et accurate colligari possunt, sine ullis erroribus. Id significat minus tempus et ita pecuniam expendi ad inveniendum meliorem modum quam quicquam ante inventum, hominibus dandae facultatis ad solvenda problema absque necessitate reinventandi rotam.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ