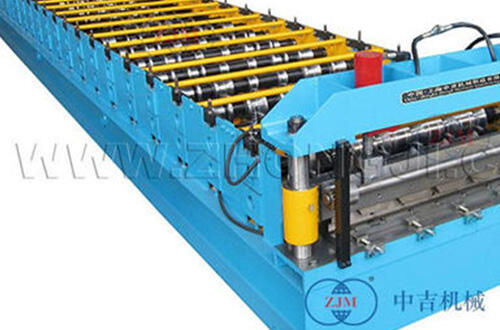

Կա՞ մաքուր պանելի գումարդիչի ռոլային ֆորմավորման մաքինա որոնք եք փնտրում? Եթե այո, դուք իդեալական վայրում եք: Ահա այստեղ է մենք կը ծածկենք շատ բացահայտումներ: Այս հոդվածում մենք կը կիսվենք խորհուրդներով roll forming machine մատակարար ընտրելու վերաբերյալ: Այս գրառման մեջ նաև կքննարկենք, թե ինչպես գտնել ձեր բիզնեսի համար ճիշտ մատակարարին: Վերջապես, կա ուղեցույց, որը օգնում է համեմատել մատակարարներին: Մենք կխոսենք որակի վերահսկողության մասին, իսկ վերջապես, կտանք մի քանի փորձագետների խորհուրդներ roll forming machine մատակարարի հետ աշխատելու վերաբերյալ:

Դա ձեր գործունեության հարց է՝ ընտրելու համար լավ և վստահելի ռոլային ձևավորման մաքինայի ասպեկտ։ Վստահելի ասպեկտն օգնում է ձեզ գտնել ամենահարմար մաքինան ձեր պահանջներին համապատասխան։ Քանի որ կարող եք հանդիսանալ խնդիրներ ձեր մաքինաների հետ, լավ գործակից սպասարկությունը հարմար է ունենալ վստահելի ասպեկտի հետ աշխատելիս։ Եվ այդ սպասարկությունը կարող է լիովին փոխել ձեր գործունեության աշխատանքը։

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ