Cad iad na Bainbhéimeanna Réadacha as Roghnú Monaróirí Líne Táirgeachta Pána Dúbailte i Seilé?

Chomh maith leis sin, bíonn ag déantóirí áitiúla línte shainiúla acu go minic. Cuireann sé seo i bhfad i bhfeidhm orthu freagairt a thabhairt go tapa do scileanna nó do iarraidh speisialta ó thaithníocháin. Is féidir le déantóirí áitiúla an cineál sin a dhéanamh ar ordú de ghnáth má éilíonn ceannaitheoir méid nó catagóir áirithe painéalacha béise. Is féidir leis an solúbthacht sin ama agus airgead a sábháil do cheannaitheoirí atá ag iarraidh a n-orduithe a chustaimiú. Ar deireadh, nuair a chinntíonn tú obair a dhéanamh le soláthraí líne painéal béise in Sile, tá go leor cúiseanna ann cén fáth is maith é sin do ghnó: táirgí ar ardchaighdeán, costais tháirgeachta ísle agus tacú le daonra áitiúil.

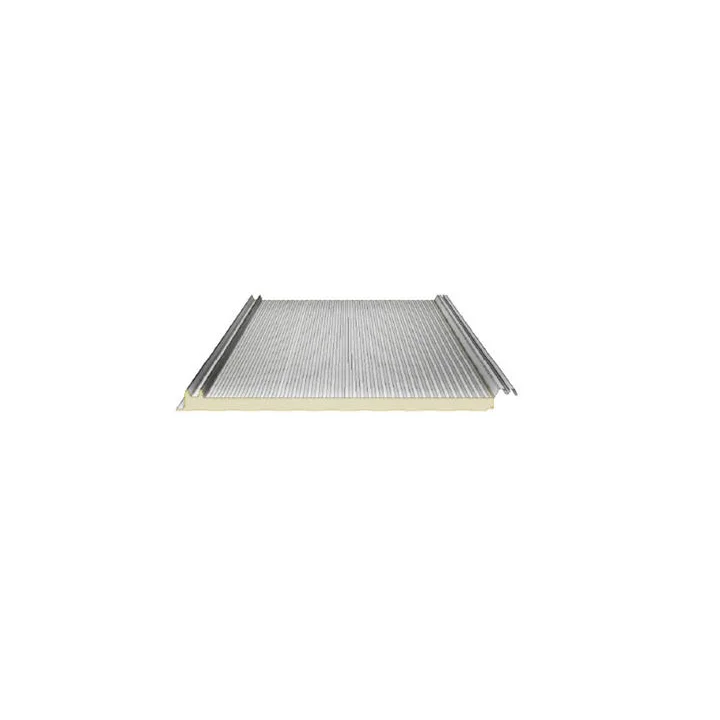

Tá go leor buntáistí le ceannach ó mhonarálanní líne táirgeachta phainéalacha sándwich i Seilé, cé go bhféadfadh ceannaitheoirí mórbhrógacha codanna beaga dúshláin a sheasamh. Bhí rialú cáilíochta ar cheann de na fadhbanna is mó a cuireadh in iúl. Uaireanta, d'fhéadfadh nach mbeadh na painéil atá curtha ina náid mar a shamhlaigh an ceannaitheoir é. D'fhéadfadh sé seo tarlú má bhí fadhbanna sa bhealach a rinneadh an vaccún. Mar shampla, d'fhéadfadh nach mbeadh na hairgí a úsáidtear ar ardchaighdeán, mar sin más ea, dá bhrí sin, ní bheidh siad láidir ná faighteoidh siad tréimhse fhada. Caithfidh ceannaitheoirí dearbhú ar chlú an chomhlachta a roghnaíonn siad. Tá Zhongji cáiliúil as a chóras rialaithe cáilíochta géar, seiceálann sé cáilíocht na dtáirgí sula gcuirtear iad ar siúl. Chun éifeachtúlacht agus cáilíocht an tábhairne a fheabhsú, úsáid Réaltaire Réad EPS Leathnúchán Idirchíneach is féidir leis dul faoi ghlas.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ