Fabrication de machines de haute qualité pour panneaux sandwich en Bolivie

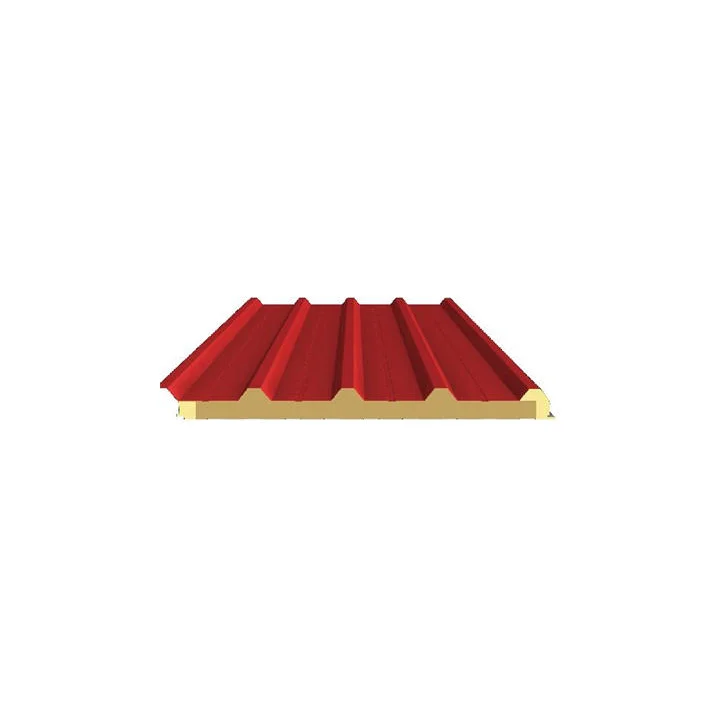

En Bolivie, la fabrication de panneaux sandwich à l'aide de machines n'est pas une mince affaire. Les panneaux sandwich sont presque comparables à un type particulier de matériau pour murs ou toitures. Ils possèdent deux couches externes rigides entourant une couche interne souple, ce qui aide à maintenir les bâtiments au chaud ou au frais. Résoudre les problèmes de qualité Lors de la production de ces panneaux avec des machines, plusieurs problèmes peuvent survenir et nuire à la qualité. Un problème courant est l'adhérence non uniforme entre les couches. Si la colle ou la chaleur utilisée pour les assembler n'est pas parfaitement dosnée, des fissures peuvent apparaître par la suite. Cela peut rendre le panneau faible et inefficace. Un autre problème concerne l'épaisseur incorrecte des panneaux. Si la machine ne coupe ou n'applique pas la pression correctement, certaines pièces peuvent devenir trop fines ou trop épaisses. Cela peut poser problème lors de leur utilisation en construction, car les panneaux ne s'ajusteront pas correctement ou ne protégeront pas efficacement contre les intempéries.

Mais en Bolivie, ces problèmes sont plus susceptibles de survenir en raison des variations climatiques, notamment les journées très chaudes et les nuits froides. De telles variations peuvent affecter le fonctionnement des machines ou l'adhérence de la colle. La poussière et la saleté peuvent également pénétrer à l'intérieur des machines, provoquant des erreurs. Bien que les machines ne soient pas particulièrement sensibles à ces problèmes, garder les outils propres et bien assemblés peut aider à tout prévenir. Des vérifications et un entretien réguliers permettent de maintenir le bon fonctionnement des machines. En outre, il est essentiel d'utiliser une bonne colle et de bons matériaux adaptés au climat bolivien. » Zhongji fabrique des machines conçues pour résister à ces aléas. Leurs machines gèrent extrêmement bien la température et la pression, de sorte que les couches adhèrent uniformément à chaque fois. Il est également important de former les travailleurs à utiliser correctement les machines. Lorsque les opérateurs savent effectuer les réglages et détecter rapidement les anomalies, les panneaux sandwich sortent solides et fiables. Notre Systèmes de plancher ICF et EPS peut également compléter vos projets de construction.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ