Shenzhen Yazhi Group

Machines:

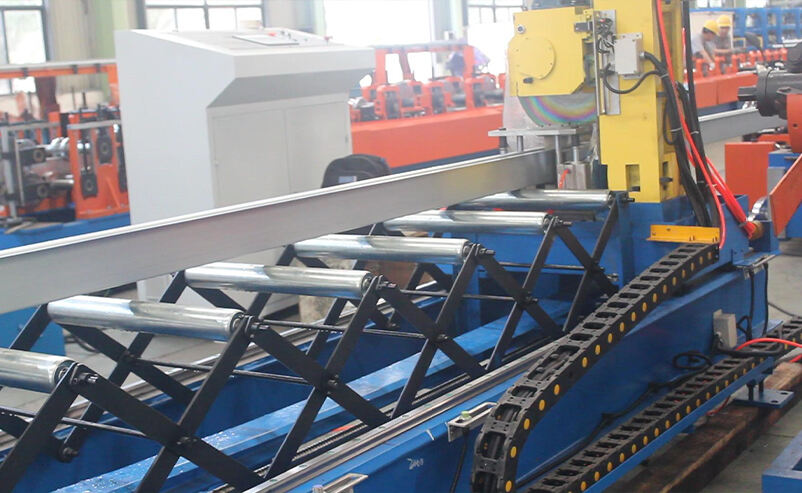

Rock wool color steel sandwich panel automatic production line is mainly composed of uncoiling system, lamination cutting, molding machine system, rock wool automatic feeding system, two-component low-pressure side foaming system, upper and lower rock wool spraying system, double-belt main machine, double-belt heating system, cutting system, stacking system, packing system and other equipment. The complete set of packaging box cold forming machine equipment consists of 5 sets of automatic cold forming machine production lines. Each set of production line consists of uncoiling, leveling, guiding, forming, cutting with saw, and discharging table.

Project condition:

Annual output:800000~1000000㎡

Whole line length:about 120 m

Labors:about 6

Double-belt effective length:12m(Reserve 6 meters)

Heating method:electric

Project background:

The client of this project specializes in the production of double-layer packing boxes and movable rooms. Metal-faced rock wool thermal insulation sandwich panel is an ideal material for multifunctional new construction and decoration. It has various superior performances such as thermal insulation, fire prevention, decoration, etc. It can be used in public buildings such as industrial plants, supermarkets, large warehouses, large-span roofs, mobile rooms, etc. It can also be used in various cold storages, clean rooms, air-conditioning rooms, communication base stations and other places. Due to its advantages of high strength, beautiful appearance, convenient construction and short construction period, it has become an ideal new building material among today's building materials, and is widely used. The traditional production line equipment has low degree of automation, high labor cost, very low product accuracy and equipment quality, and low production efficiency. After many inspections, the customer decided to invest in the fully automatic production line and packaging of rock wool color steel sandwich panels of Zhongji Machinery. A complete set of equipment for box cold bending forming machine, the production line runs well after it is put into production, and the output is stable, which has brought huge economic benefits to customers.

Project advantage:

The production line adopts domestic and foreign advanced roll forming technology, polyurethane spray technology, composite transmission technology, CNC servo control technology, frequency conversion vector control technology, and hydraulic control technology. The entire line requires only five to seven operators to operate normally. The characteristics of this production line are: high degree of automation, fast production efficiency, simple operation, low production cost and saving investment cost.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ