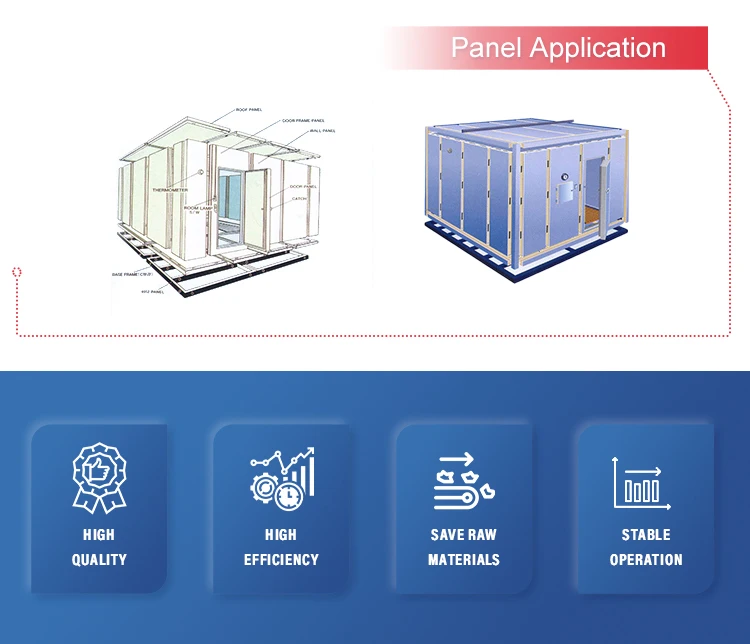

- Conspectus

- Inquisitio

- Producta Relata

Producti Details

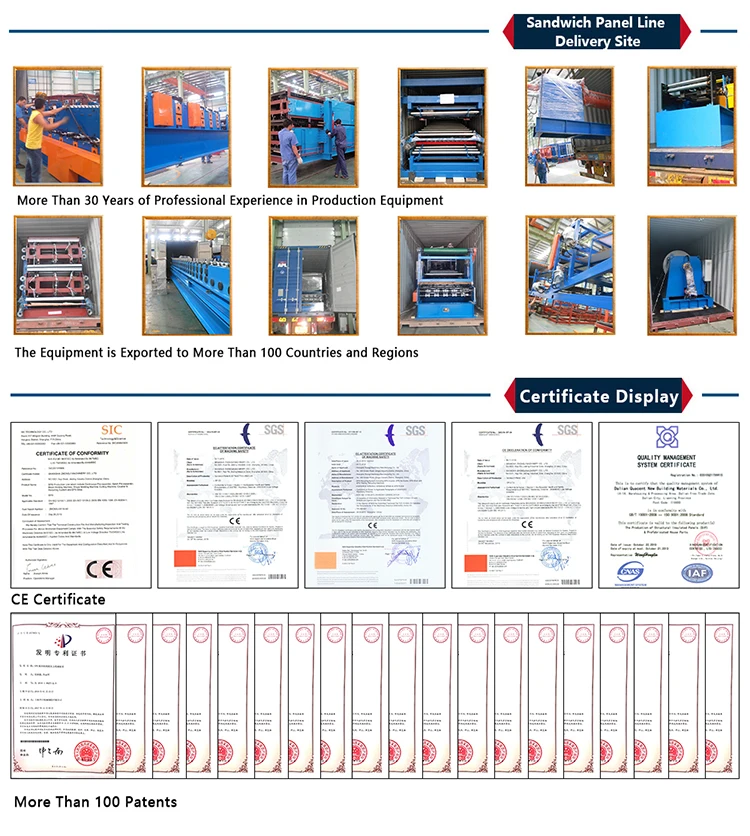

Vantagia Societatis et Servitii:

2. Societas habet professionalem Adjuster team, viginti quattuor horas sine intermissione post-venditionem servitium praebere potest.

(1) Installatio et debugging

Machina in officinam clientis pervenit, secundum planum dispositionis nostrae machinae. Disponent experientissimos technicos ad installandum, debuggandum et probandum producendum machinam, et faciendum ut machina ad ratam productionem capacitatem productionis perveniat

lineam.

(2) Training

A societate nostra praebitur instructio technica pro clientibus nostris. Instructio complectitur structuram et conservationem instrumentorum, gubernationem et operationem eorumdem; experiti technici ducere et programmatum instructionis constituere. Post instructionem, viri technici emptoris possunt operam habere et conservare instrumenta, possunt processum regere et cum variis defectibus agere.

3. Post venditionem qualitas problemata intra duas horas respondere, si telephonicus vel video ductus non potest solvere, domi 24 horas mittunt ingeniosos ad locum problema solvere.

4. Directe ex fabbrica pretium concessionis, 40,000 quadrata passuum fabrica, 20 annos Exportationis Aedificiorum, CE certificatio, patentia plus quam 100 item.

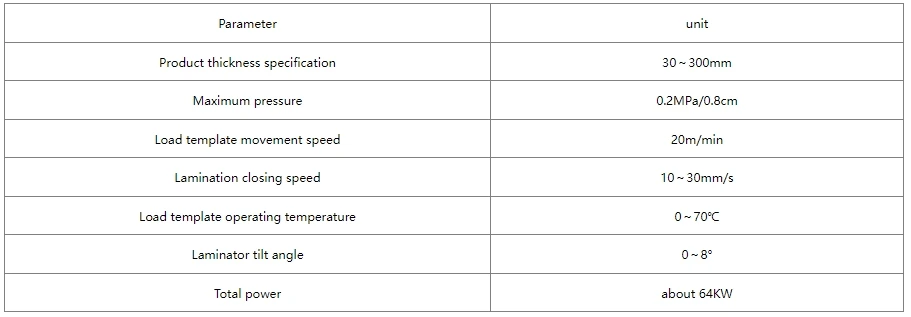

|

Items

|

GENUS/SINGULUM

|

SP-PU-C

|

|

Dimensiones Lineae (L × W × H)

|

mm

|

50000×4000×7000

|

|

Capacitas productionis

|

m²/h

|

2500

|

|

Pondus

|

kG

|

80000

|

|

Crassitudo laminae

|

mm

|

50-250

|

|

Potentia

|

w

|

54000

|

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ